The hand has never been so sensitive. A sleek sensorized glove that monitors pressure to human hands – and objects they touch – for automotive, consumer packaging, robotics and medical applications just took a step closer to real-world use.

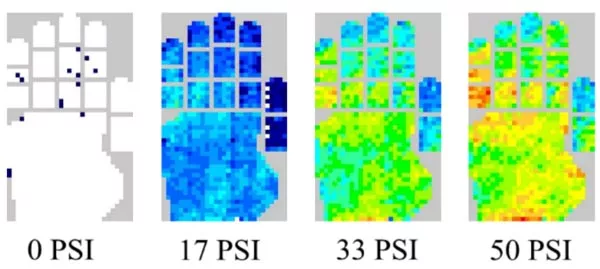

The novel glove sports a printed matrix of force-sensing cells that cover the palm and front side of the fingers and thumb with flexible conductive and pressure-sensitive ink in order to conform to the user’s hand and produce tactile pressure information. The glove delivers real-time digital and optical measurements so users can adjust their grip and touch forces to suit the objects they’re lifting, holding or carrying.

Tekscan, a provider of pressure mapping, force measurement and tactile sensors, recently completed development of the flexible, stretchable ink and substrate system needed to power the sensorized glove under SEMI FlexTech project FT19-19-187. The company funded 60% of the 18-month, $900,000 project designed to address substrate, hardware, software, and manufacturing, production scale up, design and related processes. The new technology doubles the number of sensing points over previous versions to enable pressure mapping of the entire hand for applications such as the following:

Tekscan, a provider of pressure mapping, force measurement and tactile sensors, recently completed development of the flexible, stretchable ink and substrate system needed to power the sensorized glove under SEMI FlexTech project FT19-19-187. The company funded 60% of the 18-month, $900,000 project designed to address substrate, hardware, software, and manufacturing, production scale up, design and related processes. The new technology doubles the number of sensing points over previous versions to enable pressure mapping of the entire hand for applications such as the following:

Automotive – Evaluating how drivers interact with the steering wheel and dashboard interfaces

Automotive – Evaluating how drivers interact with the steering wheel and dashboard interfaces

Consumer Packaging – Gauging hand strain as the wearer carries or uses a product

Robotics – Assessing grip force thresholds to help establish pressure standards for the safe handling of sensitive goods and produce

Medical Devices – Ensuring the hand comfort of wearers as they use medical devices

The glove advances the state of the art for pressure and force measurements and analysis to help tech companies evaluate designs of products under development.

Traditional and current thin film force-sensitive resistor (FSR) sensors implemented for various tactile force measurement applications are typically screen-printed devices composed of a combination of various functional inks (conductive, resistive, dielectric, and adhesive) usually made with a thermally cured resin material like polyester or polyimide. These FSRs perform best on a flat surface but tend to fail when bent due to the brittle polymer network within the ink and rigidity of the substrate.

TPU Version of Glove Sensor

By contrast, thermoplastic polyurethane (TPU) combines flexible polymers with hard segments for strength to enable high-tensile strength, solid low-temperature flexibility and resistance to wear during stretching and flexing.

Previous research had identified TPU as a candidate for the binder system needed for the inks. Tekscan research and development led to the creation of a TPU-based, flexible conductive, a pressure-sensitive ink system, and a flexible substrate that allowed it to create the pliable, stretchable force-sensing resistor matrix. Tekscan has produced multiple 2-D (flat) and a fully functional 3-D (full glove form factor) prototypes of a tactile sensor using a new flexible and stretchable TPU ink and substrate system.

See the Tekscan demo glove at the SEMI FlexTech booth at the upcoming FLEX Conference & Exhibition, co-located with SEMICON West 2022 Hybrid at the Moscone Center in San Francisco, July 12-14.

Register for FLEX to attend the event keynotes and for presentations on more than 60 technical papers.

Gity Samadi is director at SEMI FlexTech.