This article is the fourth in a series highlighting the vital importance of SEMI Standards to commemorate the publication of the 1000th SEMI Standard in July 2019. Find the entire series here.

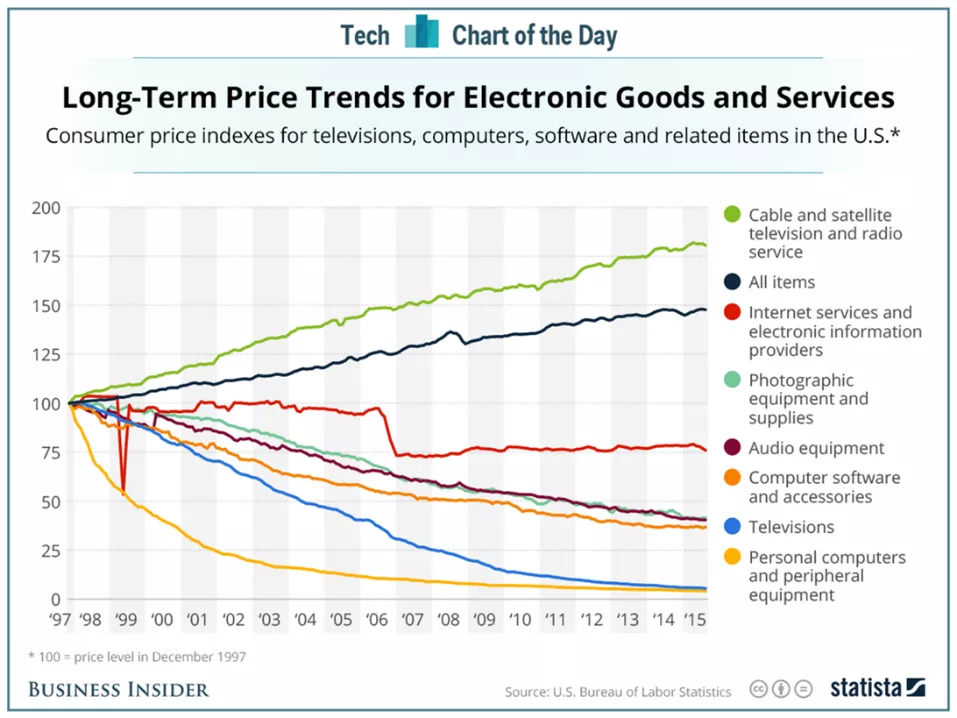

Computer prices have plunged over the years even as desktop and laptop PC performance has skyrocketed thanks to the semiconductor industry, giving users much more bang for their buck. The chip industry stands in a stark contrast to healthcare and education with their exponentially rising costs.

What distinguishes the semiconductor industry from healthcare and education in the capacity to deliver so much for so much less over time? After all, even in other parts of the technology sector that are heavily regulated, such as cable television, we have not witnessed the same price decreases as in microelectronics.

Some pundits claim that the difference among sectors is tied to their degree of regulation. Does greater regulation somehow degrade product value? The reality is far more nuanced. But one thing is clear: Smart self-regulation (i.e. standards) in the semiconductor industry has contributed mightily to its success.

The recipe for success has been simple. Standards have been rocket fuel for competition, which in turn has sparked innovation, driving down device prices while boosting performance.

Computer prices fell dramatically between 1997-2015 while the cost of cable TV and internet services rose.

Myth of unregulated competition

A semiconductor fab might actually be the most regulated place on earth. Fabs hew to a much higher standard of air quality and cleanliness than even uber-sterile hospital operating rooms. Manufacturing processes are voluntarily regulated not to millimeters, but to nanometers. While some standards are proprietary with limited reach, others span the supply chain. Regulation has worked so well in this sector that the semiconductor industry isn’t moving toward less standardization. It’s moving toward more.

Secret is smart standards

The gap between regulation and self-regulation is more like a chasm. We typically view regulation as a series of top-down directives that more often focus on the interests of the producer than the consumer. Healthcare regulation, for example, may improve quality of care, but it’s often insurers, big pharma and hospitals that benefit most from regulation, rather than consumers.

The semiconductor industry, on the other hand, uses self-regulation to improve business operations and make better products for consumers. Falling prices and rising performance are natural byproducts.

Semiconductor industry self-regulation is an ecosystem-wide effort, where input isn’t just top-down, but also bottom-up or even side-to-side. The first SEMI Standard, which specified wafer sizes, exemplifies this approach.

Semiconductor industry self-regulation is an ecosystem-wide effort, where input isn’t just top-down, but also bottom-up or even side-to-side. The first SEMI Standard, which specified wafer sizes, exemplifies this approach.

The SEMI Standards Committee formed in 1973 to address silicon wafer dimensional specifications. At the time, wafer specifications proliferated. Numbering more than 2,000, the various specifications led to major inefficiencies just when the industry was just getting underway. Wafer suppliers banded together under SEMI to solve this problem and rapidly developed consensus specifications for 2- and 3-inch wafers. By the mid-1970s, over 80% of wafers conformed to these new standards.

Standardized wafer sizes freed equipment companies to focus on innovations that reduced cost and increased performance. It also allowed manufacturers to focus on product differentiation without having to worry about device fabrication process and cost.

Since that first SEMI Standard made possible the modern semiconductor equipment industry, original equipment manufacturers (OEMs) have competed to deliver amazing innovations. For example, lithography systems routinely use light to design chips with feature sizes smaller than the wavelength of light.

SEMI’s 1000th standard on energetic materials demonstrates how smart standards are also pragmatic. This standard is not about banning materials or assigning blame when things go awry. It is about creating practical guidelines that companies will follow, enabling them to realize greater innovation. Guidelines that reduce accidents and risks will spur more, not less, energetic materials’ exploration. Industry suppliers will be the big winners.

The 1st to the 1000th SEMI standard all represent examples of cooperation making more sense than competition.

Standards for the real world

Creating a business-friendly standard that still gets the job done is a process. As SEMI Standards Task Force and Committee members, materials, equipment and manufacturing companies take part in defining best practice guidelines that support safe and practical use of materials and equipment. Task force and committee members assign particular responsibilities and associated costs to the most logical segments of the supply chain. They also develop information-sharing practices around competitive process recipes and purity standards.

Andy McIntyre, CIH, a member of the energetic materials task force and an executive vice president and managing principal at BSI EHS Services and Solutions, summarized what makes SEMI standards smart.

“SEMI standards are pragmatic,” said McIntyre. “They take into account the need for implementation in a real-world business environment. They embrace an engineering approach to problem-solving to create practical solutions, and they define specifications and performance goals in ways that allow engineers — in collaboration with EHS professionals — to identify practical solutions for reducing risk in R&D, pilot line and manufacturing operations.

“SEMI standards are pragmatic,” said McIntyre. “They take into account the need for implementation in a real-world business environment. They embrace an engineering approach to problem-solving to create practical solutions, and they define specifications and performance goals in ways that allow engineers — in collaboration with EHS professionals — to identify practical solutions for reducing risk in R&D, pilot line and manufacturing operations.

“SEMI standards employ a holistic process that considers all the important points of view throughout the supply chain, from materials selection, installation, use, recycling and/or disposal,” said McIntyre. “The breadth of SEMI EHS Guidelines, for example, is also very comprehensive as the SEMI EHS Committee and task forces work to ensure that standards keep pace with dynamic technology developments. Energetic materials is a prime example where the industry recognized the need for a new safety guideline to document safe usage of pyrophoric, water-reactive and unstable reactive materials, which have become increasingly important in semiconductor and advanced materials R&D and manufacturing.”

This is the real secret to the success of the semiconductor industry. Smart self-regulation allows industry players to cooperate in the development and implementation of standards that are pragmatic, comprehensive and dynamic. Participants in SEMI Standards have a voice in the semiconductor industry because they are the voice of the semiconductor industry.

While innovation in semiconductors may not always keep pace with Moore’s Law, we can depend on one truth: As long as collaboration and cooperation are the rule and not the exception, we will continue to advance technology in amazing and unprecedented ways. You, me and all other consumers will continue to reap the rewards of innovation.

Use your voice to affect standardization in and around the semiconductor industry. Learn about SEMI Standards – and become part of the solution.

Heidi Hoffman is senior director of technology communities marketing at SEMI. Hoffman and her team shine a spotlight on the work of the more than 20 technology communities under the SEMI electronics manufacturing supply chain collaboration platform. Actively engaging community members in marketing programs that showcase their unique value, Hoffman’s team helps companies to grow and prosper through the power of connection, collaboration and innovation.