What is IRAM?

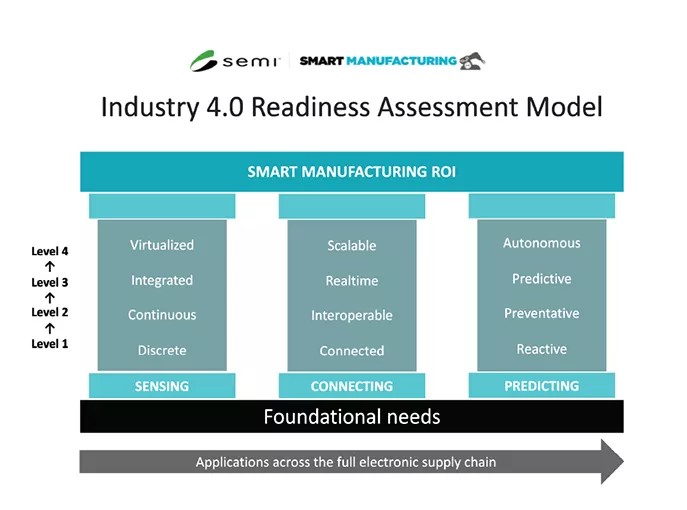

The Industry 4.0 Readiness Assessment Model (IRAM) is intended as a tool to help organizations to assess their Industry 4.0 technology deployment progress. Developed through a collaboration of SEMI and industry experts, the model is intended to guide companies across the semiconductor supply chain to identify technology enhancements critical to scaling and sustaining their smart manufacturing transformation.

Benefits

- Provide a structured model to assess the maturity level

- Determine the best starting point for the Smart Manufacturing journey

- Identify the next Industry 4.0 technology step improvements of the highest value

- Provide criteria for specific improvements

- Assist in quantifying ROI for implementation

Accelerate your smart manufacturing transformation

IRAM is an expert-crafted tool that guides semiconductor companies to initiate, optimize, and quantify returns on their smart manufacturing journey.

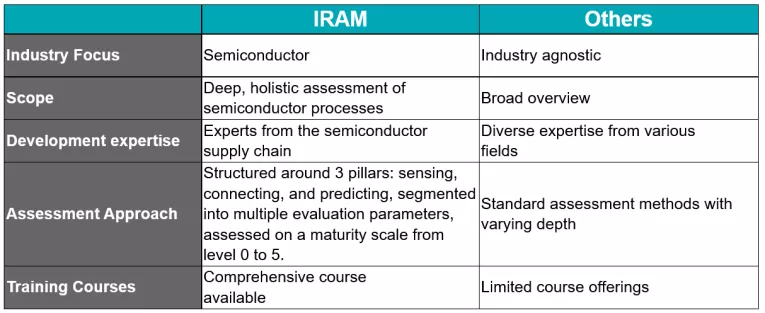

IRAM vs. others

What’s the difference?

IRAM: A maturity assessment model exclusively tailored by semiconductor industry experts, for the semiconductor industry.

Resources

IRAM is developed by the SEMI Smart Manufacturing Guidelines Sub-Committee.

The guidelines sub-committee is comprised of subject matter experts from across the supply chain that is focused on activities including the maturity models, self-assessments, benchmarking, surveys, and possible skill mapping.

IRAM is currently available as an Excel file. If you wish to keep the results of the assessment score as company confidential you're welcome to download the Excel file for your internal usage.

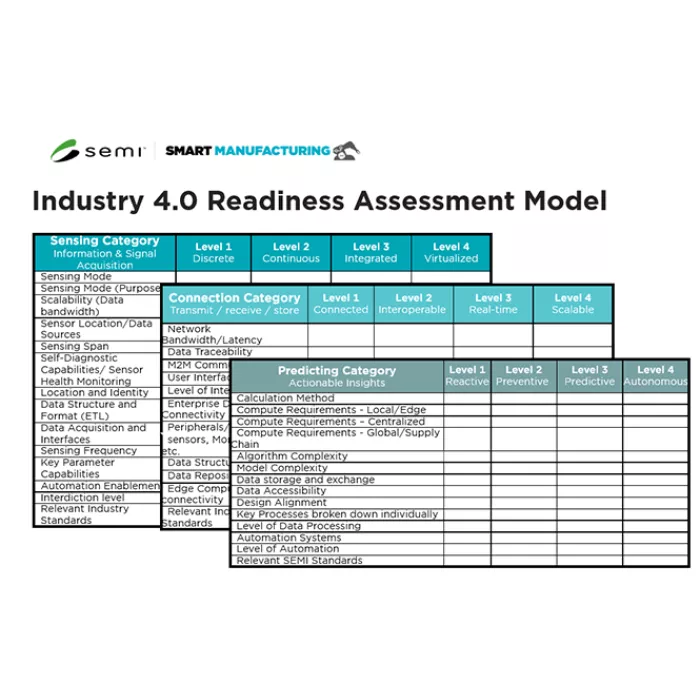

The Excel file has 4 unique tabs:

- Instructions

- Problem Statement - Details the IRAM Problem and Mission Statements

- Maturity Model

- IRAM has 4 separate categories - Foundational Requirements, Sensing, Connecting, and Predicting. Each section corresponds to various technology layers within a manufacturing line.

- Ideally, begin with the Foundational Requirements category and work your way through each of the remaining categories.

- For each item, please review the Levels 1-4 provided (Columns E-H) and match your current manufacturing line's readiness to a specific level.

- In column J select from levels 0=NA and 1-4. This is your assigned score for the existing maturity of your deployed technology layers.

-

In Column K select from levels 0=NA and 1-4. This is your assigned score for the desired maturity level of your manufacturing line.

- Glossary - Detailed reference for all terminology used within the model.

- Step 1 - Review the Instructions

- Step 2 - Starting with the Foundational Requirements section, assign appropriate scores for the "Current" and "Desired" state in columns J & K

- Step 3 - Comments may be entered in Column I in Excel or the comments section online.

Hear from Your Peers

"SEMI’s IRAM provides a well-grounded framework for the evaluation of readiness for smart manufacturing in a semiconductor fab environment. It has a very welcome focus on the technology and infrastructure needed to enable smart manufacturing."

“The IRAM model is specific enough for immediate utility and flexible enough for everything from individual operations to entire fabs or the enterprise. It will facilitate the identification of gaps and defining next steps, whether you're just beginning your Smart Manufacturing (I4.0) journey or are already well on your way.”

Who Benefits from IRAM

- Facility Operations Manager

- Industrial engineers

- Process engineers

- Data Scientist

- Industrial/ Automation Engineer

- Chief Information Officer

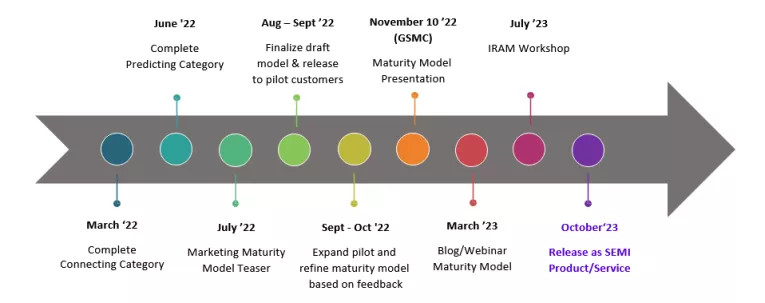

IRAM Product Evolution

IRAM Development Timeline