Technical Committee Charter

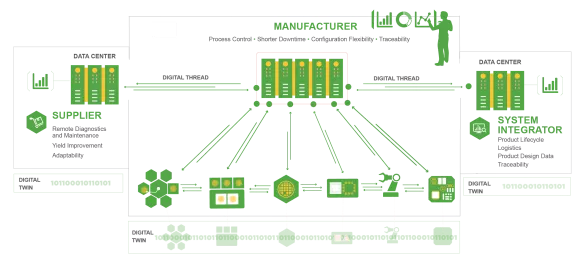

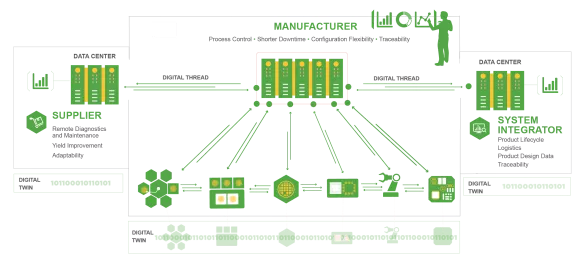

To explore, evaluate, discuss, and formulate consensus-based specifications that through voluntary compliance, will enhance the manufacturing capability of the semiconductor industry. The Committee scope includes exploring and developing standards that pertain to the interface of manufacturing tools to each other, to control computers, or to human operators, for the purpose of transferring commands and data used during the manufacturing process.

- Backend Factory Integration Task Force

- Diagnostic Data Acquisition (DDA) Task Force

- Fab & Equipment Information Security Task Force

- GEM 300 Task Force

- Information & Control Committee Maintenance Task Force

- Sensor Bus Task Force

- Advanced Backend Factory Integration Task Force

- Diagnostic Data Acquisition (DDA) Task Force

- GEM 300 Task Force

- Advanced Backend Factory Integration (ABFI) Task Force

- Diagnostic Data Acquisition (DDA) Task Force

- Energy Saving Equipment Communication (ESEC) Task Force

- Fab & Equipment Computer and Device Security (CDS) Task Force

- GEM 300 Task Force

- Graphical User Interfaces (GUI) Task Force

- Process Control Systems (PCS) Task Force

- Sensor Bus Task Force

- Backend Factory Integration Task Force

- Equipment Information Integration Task Force

- Fab & Equipment Information Security Task Force

- GEM 300 Task Force

Published Standards*

COMMUNICATION PROTOCOLS

SEMI E4 — Specification for SEMI Equipment Communications Standard 1 Message Transfer (SECS-I)

SEMI E5 — Specification for SEMI Equipment Communications Standard 2 Message Content (SECS-II)

SEMI E37 — Specification for High-Speed SECS Message Services (HSMS) Generic Services

SEMI E39 — Specification for Object Services: Concepts, Behavior, and Services

EQUIPMENT CONTROL

SEMI E30 — Specification for the Generic Model for Communications and Control of Manufacturing Equipment (GEM)

SEMI E40 — Specification for Processing Management

SEMI E84 — Specification for Enhanced Carrier Handoff Parallel I/O Interface

SEMI E87 — Specification for Carrier Management (CMS)

SEMI E90 — Specification for Substrate Tracking

SEMI E94 — Specification for Control Job Management

EQUIPMENT DATA ACQUISITION & PROCESS DIAGNOSTICS

SEMI E120 — Specification for the Common Equipment Model (CEM)

SEMI E125 — Specification for Equipment Self Description (EqSD)

SEMI E128 — Specification for XML Message Structures

SEMI E132 — Specification for Equipment Client Authentication and Authorization

SEMI E134 — Specification for Data Collection Management

SEMI E138 — Specification for XML Semiconductor Common Components

SEMI E164 — Specification for EDA Common Metadata

ADVANCED ANALYTICS AND PROCESS CONTROL

SEMI E116 — Specification for Equipment Performance Tracking

SEMI E126 — Specification for Equipment Quality Information Parameters (EQIP)

SEMI E133 — Specification for Automated Process Control Systems Interface

SEMI E157 — Specification for Module Process Tracking

DATA MANAGEMENT

SEMI E151 — Guide for Understanding Data Quality

SEMI E160 — Specification for Communication of Data Quality

SEMI E172 — Specification for SECS Equipment Data Dictionary (SEDD)

SEMI E173 — Specification for XML SECS-II Message Notation (SMN)