SEMI Standards are voluntary technical agreements for the semiconductor, flat panel display, micro-electromechanical systems, photovoltaic, and high-brightness LED industries.

The SEMI International Standards Program is a key service offered by SEMI for the benefit of the worldwide electronics design and manufacturing industries. The program, started over 50 years ago in North America, was expanded in 1985 to include programs in Europe and Japan, and now also has technical committees in China, Korea and Taiwan.

SEMI Standards Overview

Paul Trio explains SEMI Standards in this video. Learn the Why, What & How of the program, and understand how you can propose a new standard, or get involved with a current committee.

Questions? We have answers

The SEMI International Standards Program is a key service offered by SEMI for the benefit of the worldwide electronics design and manufacturing industries. The program, started over 45 years ago in North America, was expanded in 1985 to include programs in Europe and Japan, and now also has technical committees in China, Korea and Taiwan. Since its inception, SEMI has underwritten the cost of administering the program as a service to the industry.

Standards are voluntary technical agreements between suppliers and customers, aimed at improving product quality and reliability at a reasonable price and steady supply. Standards ensure compatibility and inter-operability of goods and services. SEMI Standards are written documents and can take the form of specifications, guides, test methods, terminology, or best practices. Documents are published in a 16 volume set called SEMI International Standards.

Standards help the industry meet the challenges of increasing productivity, encouraging innovation, global expansion and training new workers. The program operates as a neutral forum for exchanging information between suppliers and users, which results in the production of timely and technically accurate specifications and guidelines. Companies utilizing standards can decrease manufacturing costs, increase reliability and productivity, and access global markets. Standards transcend international boundaries.

More importantly, SEMI Standards development conducted on an international basis spurs the dialogue that results in joint ventures, technology licenses, and sales. Standards are not just developed by and for engineers; their use is also a management tool, often a business strategy, and consequently should be accompanied by high level support for standards-setting activities.

Standards can:

Increase supplier profitability by:

- reducing product development cost and cycle time

- increasing reliability

- allowing focus on unique value-added features

- enhancing market penetration/ensuring product acceptance

- remaining at the forefront of technological advancements

- smoothing technology migration

Increase Customer Satisfaction by:

- reducing factory integration costs and production ramp time

- lowering manufacturing costs

- minimizing maintenance costs

- clarifying expectations for suppliers

- enabling incremental change at proportional cost

Increase Industry Efficiency by:

- reducing/eliminating duplication of efforts

- providing level of commonality

- defining new markets

- promoting competition by lowering barriers to entry

- enabling evolving technology trends

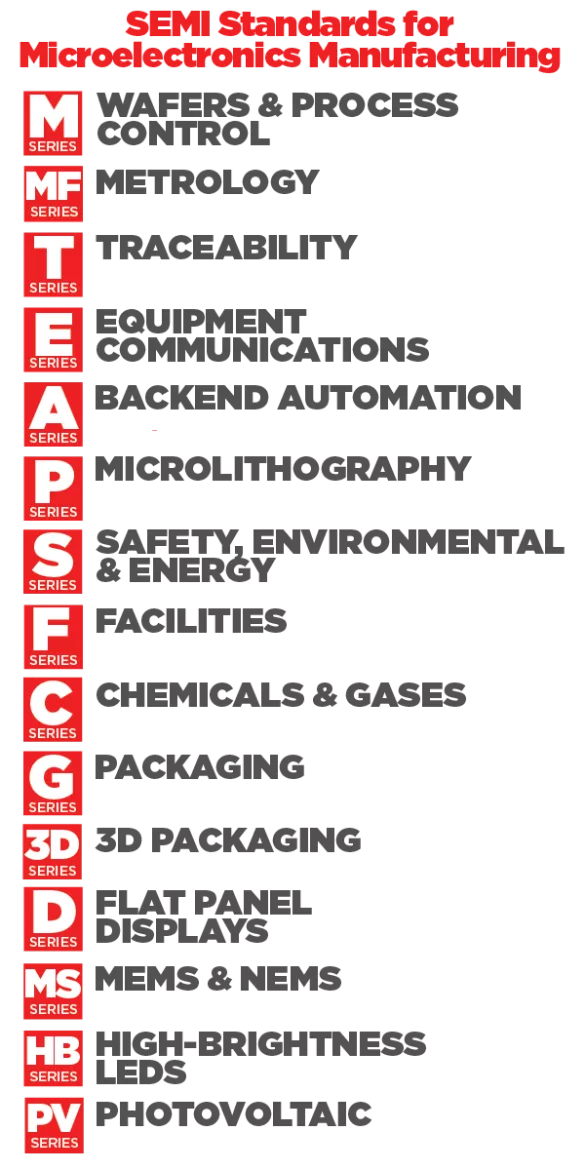

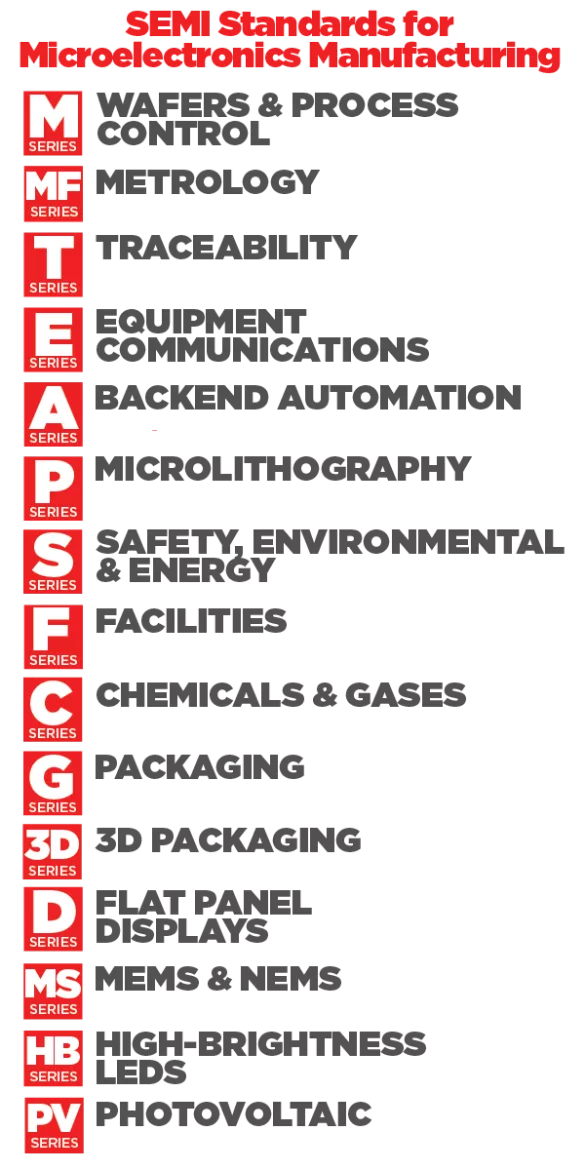

SEMI Standards cover many topics related to electronics manufacturing: 3D-IC, Equipment Automation (Hardware and Software), Flat-Panel Displays, Facilities, Gases, High Brightness-LED, MEMS/NEMS, Materials, Microlithography, Packaging, Photovoltaic, Process Chemicals, Silicon Material & Process Control, and Traceability. Guidelines are also developed to cover safety related issues.

The best way to find a specific standard is to visit the publication catalog and use keywords in the SEARCH tool to find applicable standards or guidelines.

The SEMI International Standards Program is first and foremost an opportunity for industry representatives to participate in state-of-the-art technical discussions, while also establishing the future direction of the semiconductor, photovoltaic, and FPD industries. By participating in Standards, companies can influence important industry trends. On an individual level, participation helps reduce design work, provides access to evolving technology and technical developments, and aides personal development. It is a vehicle for networking, partnership, and professional growth. Over 5,000 technologists worldwide, representing all levels of the supply chain, convene to resolve an increasing variety of process and product related issues.

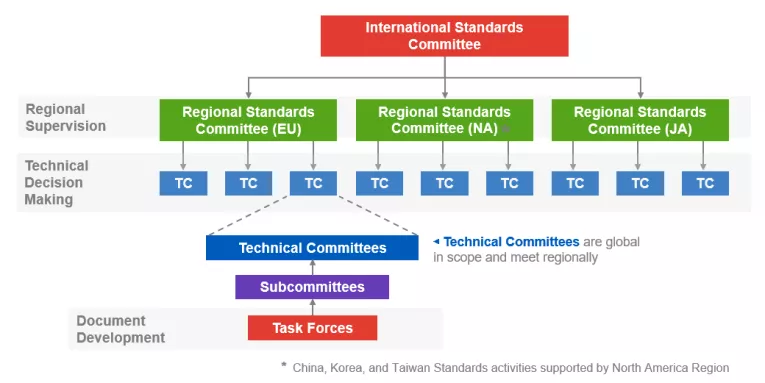

The SEMI International Standards program provides the framework and procedures for industry experts to meet, discuss, and develop essential standards and guidelines. Once the need for a standard has been identified with appropriate input from the user community, a task force is assembled to carry out the development effort. The task force may be regional or international. The result of the task force deliberations is a draft document responsive to industry needs. The draft is reworked until the task force develops a consensus. Once the task force is satisfied with its work, a wider consensus is developed by reporting to the parent regional technical committee or subcommittee to obtain comments from other members who did not participate directly in the document development.

Frequently, broader international consensus is also obtained informally at this time. When the regional technical committee agrees that a reasonable consensus has been reached, it will initiate a worldwide balloting process to confirm that the document has global consensus.

This process is managed by the SEMI Headquarters office. Regional offices in China, Europe, Japan, Korea, and Taiwan provide additional direct member interface. At least 60% of the issued ballots must be returned, so it is very important for ALL registered technical members to vote. All negative viewpoints must be considered, but unanimous agreement is not required.

The culmination of the development effort is the application of the new standard by the industry - frequently by citing them in their purchase specifications or utilizing them in equipment and materials evaluations. In addition, suppliers might cite conformance of equipment, materials, or services to SEMI standards in their advertising and product literature. Use of SEMI standards is entirely voluntary

SEMI also organizes Standards Technical Educational Programs (STEPs) and Fab Accelerator Programs to communicate new standards to the industry and show the advantages of using them.

Standards Certification

SEMI does not perform accreditation or provide certification for any of its standards, however, there are unaffiliated third party evaluators, often experts in their fields of safety, loss control, engineering, industrial hygiene, fire prevention, product safety, and other fields. SEMI suggests searching our Membership Directory for assistance.

In addition, NRTL, or Nationally Recognized Testing Laboratory, are third-party organizations recognized by OSHA as having the capability to provide product safety testing and certification services to the manufacturers of a wide range of products for use in the American workplace. The testing and certifications are based on product safety standards developed by U.S.-based standards developing organizations. For more information on NRTLs, please visit the OSHA website.

New standards activities are proposed regularly and there is an established process to gather people to efficiently begin a new activity. To propose a new activity, download and complete a SEMI New Activity Report Form (SNARF) and send to your local SEMI Standards Staff Member.

Management of the program is provided by industry volunteers serving on administrative Regional Standards Committees in all SEMI Regions. Committees consider the document history to confirm all mandated procedures have been followed, and all opinions have been properly considered. The International Standards Committee has the overall responsibility for the conduct of the program and establishes the regulations governing the program procedures. The committee also maintains relationships with other standard-setting organizations worldwide to minimize duplicative efforts and cooperate as appropriate.

Yes. SEMI activities are subject to antitrust laws as SEMI activities are a coordinated effort among competitors in the semiconductor equipment and materials industry. Follow the link to the complete text of the SEMI Standards Antitrust Reminder.

No. The program is available to the worldwide semiconductor industry without a membership fee. Participation is independent of whether your company is a SEMI corporate member or not. How can I join the SEMI Standards Program? SEMI Standards activities are open to all interested parties, but you must be a registered SEMI Standards Program Member to participate in SEMI Standards meetings.

There are no fees required to participate in the SEMI International Standards Program. SEMI Standards Program Membership is independent of the Corporate, Associate or Affiliate SEMI memberships.

Periodically, SEMI offers training courses, called STEP. Find out more.

More information is available online for SEMI E10, the Equipment Reliability, Availability, Maintainability and Productivity (RAMP) standard, and its closely-affiliated SEMI E79, RAM and Utilization Specification Standard.

Watch the video to learn more and see how SEMI Standards are applied to new technologies based on industry needs.

SEMI Standards Committees & Task Forces

The SEMI Standards process relies on experienced members and an established set of global committees and task forces to ensure SEMI Standards and topics are considered tools for the industry.

Contact SEMI staff if you have any questions or concerns.