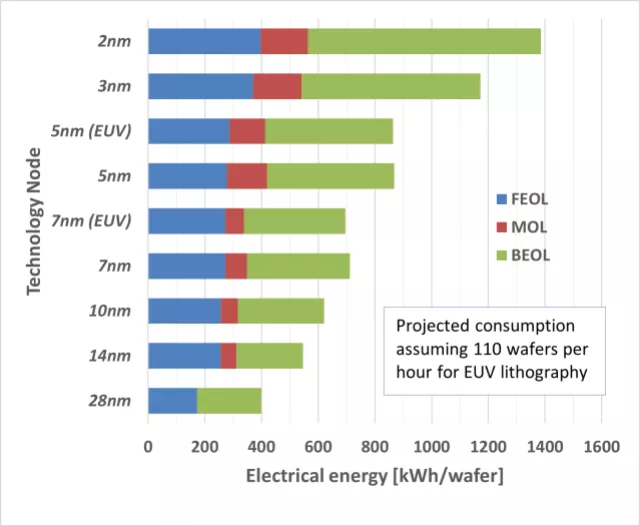

Large semiconductor fabs currently consume a staggering 100 MW of electricity per hour, equivalent to powering 50,000 houses. Moreover, a single fab can utilize up to 9 million gallons of water daily. With over 70 new fabs expected to be operational in the coming years, it is crucial to address these resource-intensive challenges.

As semiconductor technology advances, the following aspects will become increasingly important:

- Industry 4.0 Smart Manufacturing: Embracing Industry 4.0 principles leads to improved operational efficiency and minimizes waste.

- Energy and Water Conservation: Development of technologies that conserve energy and water resources while reducing the overall carbon footprint.

Ref: IMEC SEMICON WEST’21

Our mission is to extend the Autonomous Factory roadmap, incorporating specific sustainability goals that align with Scope 1 and Scope 2 emissions. These objectives will be achieved through the strategic implementation of Smart Manufacturing elements.

Some of the critical levers are:

- Integrated tool and subfab states in FDC

- Model predictive control at factory-facilities loop

- Intelligent idle/power-off mode based on process state

- Advancements in vacuum/abatement technology

- AI/ML optimized recipes for end-to-end energy & DIW

- Predictive maintenance, IIoT for sensors for chillers/boilers etc.

- Alternate process gas chemistries

Questions?

For more information about the SEMI Smart Manufacturing initiative, contact Mark da Silva at smartmfg@semi.org.