In the challenging world of high-volume manufacturing, rigorous inspection and monitoring of production systems is critical in order to meet high product quality and safety standards. By employing advanced machine vision, digital twinning and machine learning methods, high-speed metrology systems can dramatically increase overall product quality management control.

The first of its kind, the Metrology Advances for Digitized ECS Industry 4.0 (MADEin4) project aims to develop the next generation of metrology tools, machine learning methods and applications to help drive higher manufacturing productivity in the semiconductor and automotive industries. A consortium of nearly 50 European manufacturers and research and technology organizations (RTOs) will develop the Industry 4.0 solutions for the European semiconductor manufacturing industry under the three-year project funded by Electronic Components and Systems for European Leadership Joint Undertaking (ECSEL JU).

SEMI, a MADEin4 consortium member, spoke with Project Coordinator Ilan Englard of Applied Materials Israel Ltd. and Olaf Kievit, Dissemination, Exploitation and Standardization work package leader of the Netherlands Organization for Applied Scientific Research (TNO), for an update on MADEin4 since its launch nearly a year ago.

SEMI: The ECSEL JU funded project MADEin4 was kicked-off nearly a year ago. What has been achieved so far?

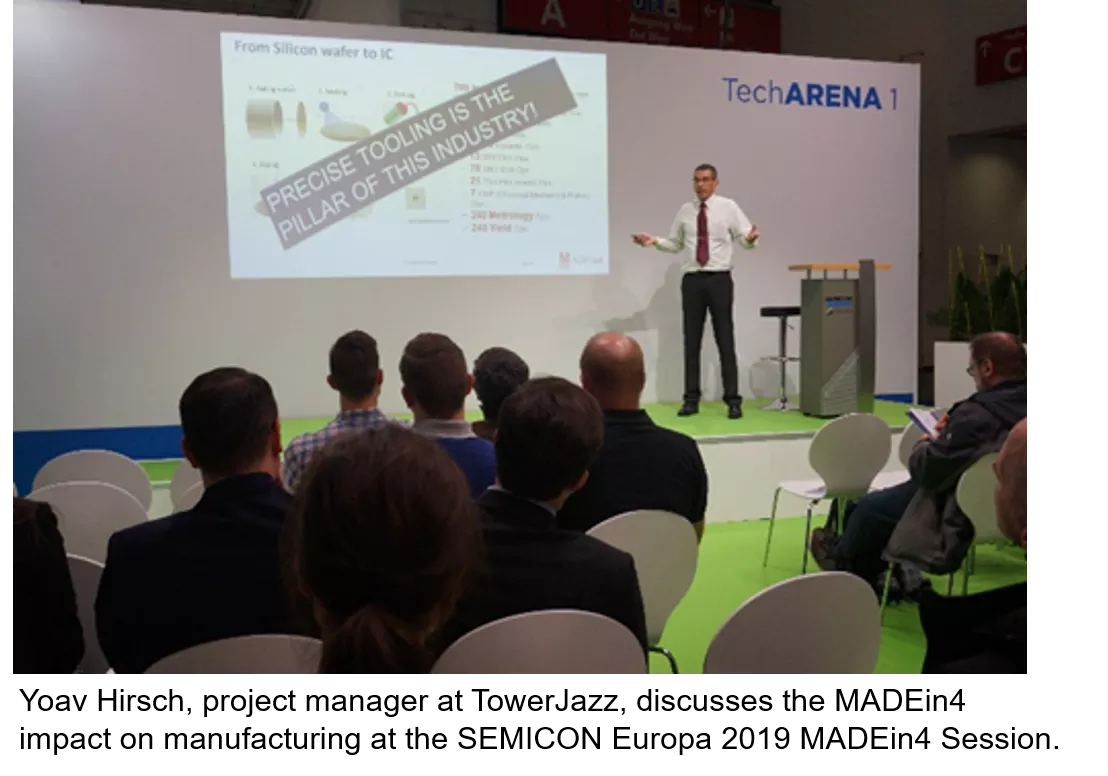

Kievit: MADEin4 has made several advances in the past several months. The promotion of the project during SEMICON Europa 2019 through a dedicated Tech Arena panel session and Innovation Hub corner counts as a major success. We also launched ongoing surveys on metrology and Industry 4.0 standardization, a significant achievement in our first year.

Kievit: MADEin4 has made several advances in the past several months. The promotion of the project during SEMICON Europa 2019 through a dedicated Tech Arena panel session and Innovation Hub corner counts as a major success. We also launched ongoing surveys on metrology and Industry 4.0 standardization, a significant achievement in our first year.

Englard: In the first months of the project, MADEin4 partners launched discussions of the needs and objectives of individual work packages. We also implemented data sharing mechanisms and rules, a major achievement for our ongoing workflow and future qualifications of new technologies.

SEMI: The majority of manufacturers is looking into next-generation metrology in search of ways to handle inspection tasks, and in turn, be more productive, profitable and ecological in high-volume manufacturing. How will MADEin4 help the modern factory achieve improved production processes and resource efficiency?

Kievit: By evolving Industry 4.0 metrology technologies, the project will be a major stepping stone for manufacturers looking to improve their production operations. Benefiting from a broad project consortium, the MADEin4 technologies will find their way into applications in industry to drive new ecological and economic efficiencies for Europe’s semiconductor manufacturers.

Englard: MADEin4 aims to bring optimized production line efficiency and profitability to the next level. The new generation of metrology, artificial intelligence (AI) and machine learning techniques, combined, will significantly boost the productivity and profitability of Europe’s manufacturing industries.

SEMI: Uptake of innovation in key enabling technologies is essential for Europe’s competitive leadership in the era of digital economy. How can future EU projects benefit from the results delivered by MADEin4?

Kievit: As part of the ECSEL JU family, we and other partners can build on the results of previous projects and initiatives. By contributing to the ECSEL JU ecosystem, the MADEin4 accomplishments in metrology will serve as the foundation for future projects, contributing to the larger whole to advance key enabling technologies in Europe.

Kievit: As part of the ECSEL JU family, we and other partners can build on the results of previous projects and initiatives. By contributing to the ECSEL JU ecosystem, the MADEin4 accomplishments in metrology will serve as the foundation for future projects, contributing to the larger whole to advance key enabling technologies in Europe.

Englard: As the first-of-its-kind metrology project, MADEin4 will lay the groundwork to improve manufacturing efficiency through advanced metrology. As part of the Lighthouse Industry 4.E family, the project interacts with initiatives and associated projects that bring innovation directly to the semiconductor and automotive industries. By addressing the standards, metrology and inspection-specific needs of semiconductor and automotive manufacturers, MADEin4 will spur next-generation Industry 4.0 projects.

SEMI: The industry has to overcome apprehensions about automating and digitization of the manufacturing processes, with greater obstacles frequently being initial financial investment and manpower required. Do you perceive EU-funded projects as means to advance adoption of innovative technologies?

Kievit: At TNO, we perceive EU-funded projects as a way to multiply our own investments in technological innovation. By aligning project objectives with our own innovation roadmaps, we pursue development with our customers, suppliers and partners, making it easier to organize large-scale developments we would otherwise not be able to pursue on our own.

Englard: EU-funded projects are essential in advancing the adoption of innovative technologies. By involving the entire value chain – from end user manufacturers to suppliers and designers from different countries – the projects are resulting in unique solutions. EU funding is especially valuable for SMEs, providing them with resources necessary for high-risk research and development activities. By reducing the financial hurdles, EU-backed projects serve as a platform for standalone companies to engage cooperation with greater confidence.

SEMI: What is your expectation for the metrology of the future and overall Industry 4.0 enabling technologies in Europe?

Kievit: More metrology techniques are getting increasingly combined. The increased rollout of hybrid methods – along with the incorporation of machine learning, data analysis and AI – empowers the development of advanced inspection tools and monitoring processes. These are the general trends that will determine the metrology of the future.

Englard: MADEin4 integrates sensors with cyber-physical systems, machine learning and AI. By doing so, it opens up the opportunity for metrology equipment to harvest large amounts of manufacturing and machinery data, improving overall manufacturing performance.

SEMI: For its part, SEMI is the member and key partner of the MADEin4 consortium for dissemination, exploitation and standardization. Where do you see the main advantages of SEMI as a project partner?

Kievit: SEMI’s extensive network of industry experts and organizations and its industry standards expertise are crucial for MADEin4 to disseminate information to the industry and establish project standards to ensure the success of each work package. Personally, as a work package leader, I cannot imagine a partner more proactive and contributing than SEMI. Your work is highly appreciated.

Kievit: SEMI’s extensive network of industry experts and organizations and its industry standards expertise are crucial for MADEin4 to disseminate information to the industry and establish project standards to ensure the success of each work package. Personally, as a work package leader, I cannot imagine a partner more proactive and contributing than SEMI. Your work is highly appreciated.

Englard: It can be a challenge to disseminate the outcomes of large projects like MADEin4 to the industry. As a key partner of the project, SEMI connects the dots between the different innovations and outcomes of different tasks, exposing European projects’ excellence world-wide. In my opinion, SEMI’s global infrastructure and expertise are key for the success of these projects.

Official disclaimer: MADEin4 has received funding from the ECSEL JU under grant agreement No 826589. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and France, Germany, Austria, Italy, Sweden, Netherlands, Belgium, Hungary, Romania and Israel.

Marek Kysela is EU policy and project coordinator at SEMI Europe.