Air pollution is a serious public health issue worldwide with airborne hazardous substances such as volatile organic compounds (VOCs), particle matter (PM), and nitrogen dioxide linked to a wide range of adverse health conditions. According to the World Health Organization (WHO), “the combined effects of ambient (outdoor) and household air pollution cause about seven million premature deaths every year, largely as a result of increased mortality from stroke, heart disease, chronic obstructive pulmonary disease, lung cancer and acute respiratory infections.”

There’s also an economic impact of air pollution. Related illnesses and loss of life cost billions of dollars in healthcare services globally. And while we might think that air pollutants are only present outdoors, we’re more exposed to them – and they’re more potentially dangerous – indoors, where higher concentrations of volatile organic compounds (VOCs) produced by paint and furniture are a major concern. The COVID-19 pandemic has only heightened our awareness of the air we breathe. With recent medical research showing that viruses may be transmitted by attaching themselves to airborne particles, indoor air quality (IAQ) monitoring is becoming even more important.

As we turn to VOC sensors for IAQ monitoring, it’s important to note that not all VOC sensors are equal. The current crop of low-cost VOC sensors are primarily total VOC sensors. Generally based on electrochemical or metal-oxide transducers, total VOC sensors provide a “grayscale” image of IAQ, which doesn’t differentiate among different gases. This limits people’s ability to make informed decisions regarding the level of threat to their health, since not all VOCs are equally hazardous and don’t require detection at the same concentrations.

As we turn to VOC sensors for IAQ monitoring, it’s important to note that not all VOC sensors are equal. The current crop of low-cost VOC sensors are primarily total VOC sensors. Generally based on electrochemical or metal-oxide transducers, total VOC sensors provide a “grayscale” image of IAQ, which doesn’t differentiate among different gases. This limits people’s ability to make informed decisions regarding the level of threat to their health, since not all VOCs are equally hazardous and don’t require detection at the same concentrations.

In addition, total VOC sensor technologies don’t support PM detection. This forces end-device designers to either add a module of optical sensors or switch to a completely different system. While optical sensors provide excellent performance, particularly for PM detection, they’re much more expensive, as well as more complex, bulky and power-hungry. This makes them ill-suited to resource-constrained portable devices where cost, size and power are at a premium.

FBAR-based IAQ sensors emerge

The shortcomings of available technologies for IAQ sensors has boosted the development of alternative solutions that provide better performance – in terms of both sensitivity and selectivity – as well as greater versatility, lower cost and smaller size. Acoustic sensor technologies featuring the latest advancements in film bulk acoustic resonator (FBAR) sensors are emerging as a leading candidate.

Sensitivity is important in VOC detection because certain hazardous compounds, such as formaldehyde, are dangerous at very low concentrations. As highly sensitive devices, FBARs are a MEMS equivalent of a weight scale, but instead of detecting kilograms or grams, they can sense femtograms, which are just one-quadrillionth of a gram each. FBARS work by putting a thin film piezoelectric material into a mechanical resonance through application of an AC electric signal (GHz range) to a pair of electrodes on either side of the film. This resonant frequency is sensitive to the mass attached to the electrode surface. Whenever the mass attaches to the active area of the sensor, it produces a frequency shift, and this shift is proportional to the mass attached on the surface.

Sensitivity is important in VOC detection because certain hazardous compounds, such as formaldehyde, are dangerous at very low concentrations. As highly sensitive devices, FBARs are a MEMS equivalent of a weight scale, but instead of detecting kilograms or grams, they can sense femtograms, which are just one-quadrillionth of a gram each. FBARS work by putting a thin film piezoelectric material into a mechanical resonance through application of an AC electric signal (GHz range) to a pair of electrodes on either side of the film. This resonant frequency is sensitive to the mass attached to the electrode surface. Whenever the mass attaches to the active area of the sensor, it produces a frequency shift, and this shift is proportional to the mass attached on the surface.

Another major benefit of this approach is selectivity, which allows a device to distinguish between different target molecules or species. By placing a layer of material on the sensor –which is the functionalization layer – FBAR sensors display high selectivity on targeted materials. This allows the consumer to distinguish among different VOCs instead of just measuring a mixture of VOCs that vary in toxicity.

Unlike older IAQ sensing technologies, FBAR sensors support functionalization layers comprised of different materials, from metal oxides and polymers to more exotic options such as carbon nanotubes and graphene. This increased versality makes it easier to use FBARs for a variety of applications, ranging from gas sensors to medical sensors.

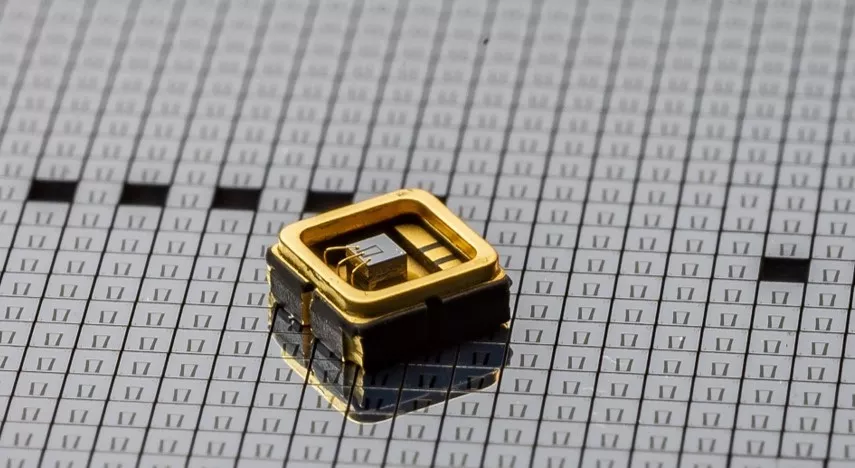

Sorex Sensors’ FBAR sensor in a 3mm x 3mm ceramic package

FBAR technology is a perfect match for IAQ. In addition to high sensitivity and selectivity, it enables the manufacture of very small arrays, and it’s low-power, all of which make it a good choice for small portable devices. Plus FBAR technology is CMOS-compatible, so FBAR sensors can be made using standard MEMS processes and combined with integrated circuits fabricated using standard CMOS processes, making them cost-effective.

With its origins at the University of Cambridge in the UK, Sorex Sensors is leading the commercialization of FBAR devices for sensing applications. After releasing our first product in 2019 – a standalone FBAR sensor and a development kit that can be used for particle monitoring – we’re preparing to release an FBAR sensor array that detects five different gases later this year. By offering specific functionalization layers for different targets, our new FBAR technology will provide a level of selectivity that other silicon-based sensors can’t achieve – particularly in light of FBAR’s low power consumption and very small size (less than 5mm x 5mm). In addition, the sensor’s targeted gases will include one of the main headaches in the IAQ space, formaldehyde, which is especially carcinogenic and is widely found in the varnishes used in furniture.

We’re planning for this new iteration of our FBAR technology to help our customers sense in color rather than in grayscale – providing a level of granularity that’s unmatched in IAQ sensing. Check out the latest news about Sorex Sensors on our website and on LinkedIn.

About the Author

Mario de Miguel Ramos, Ph.D., is the co-founder and CEO of Sorex Sensors Ltd, a spin-out of the University of Cambridge, the University of Warwick, and the Universidad Politecnica de Madrid (UPM). Founded in 2017, the company focuses on the development of highly sensitive mass sensors based on film bulk acoustic resonators (FBARs). Dr de Miguel Ramos has been working in the field of FBARs for a decade. Prior to founding Sorex Sensors, he worked as a postdoctoral research associate at the Electronic Devices and Materials (EDM) Group at the University of Cambridge. He holds a master’s in Telecommunications Engineering and a Ph.D. in Electronic Engineering Systems, both from UPM.

Mario de Miguel Ramos, Ph.D., is the co-founder and CEO of Sorex Sensors Ltd, a spin-out of the University of Cambridge, the University of Warwick, and the Universidad Politecnica de Madrid (UPM). Founded in 2017, the company focuses on the development of highly sensitive mass sensors based on film bulk acoustic resonators (FBARs). Dr de Miguel Ramos has been working in the field of FBARs for a decade. Prior to founding Sorex Sensors, he worked as a postdoctoral research associate at the Electronic Devices and Materials (EDM) Group at the University of Cambridge. He holds a master’s in Telecommunications Engineering and a Ph.D. in Electronic Engineering Systems, both from UPM.

Sorex Sensors is a member of MEMS & Sensors Industry Group®(MSIG), a SEMI technology community that connects the MEMS and sensors supply network in established and emerging markets to enable members to grow and prosper. Visit us today.