Our home state of California has wilderness areas of extreme climates, from desert to high-altitude snow-capped mountains. Every year, people need rescue because they’ve ventured into the wilderness without proper training, or even essential gear, such as water or a warm parka.

Many MEMS product development teams get a similar start. They undertake a challenging multi-year journey without enough of the most precious resource needed for success – enough money to finish.

As a MEMS product development firm that's completed more than 400 projects, 25% of these with startup companies, we’ve been having many of the same conversations about the road to commercialization with MEMS entrepreneurs. Through that experience, we’ve seen a share of these entrepreneurs – many of whom come right from graduate programs or from outside the semiconductor industry – experience disappointing outcomes.

And it’s not because of their technology. Rather, their lack of familiarity with electronic product integration and wafer-based manufacturing often influences a too-optimistic development plan that doesn’t factor in enough time and budget. As technologists, it was tough for us to see companies with promising young technologies struggle due to lack of planning or funding. We would like to see more entrepreneurs succeed, and that was the impetus for our new book, MEMS Product Development: From Concept to Commercialization, some highlights of which follow.

And it’s not because of their technology. Rather, their lack of familiarity with electronic product integration and wafer-based manufacturing often influences a too-optimistic development plan that doesn’t factor in enough time and budget. As technologists, it was tough for us to see companies with promising young technologies struggle due to lack of planning or funding. We would like to see more entrepreneurs succeed, and that was the impetus for our new book, MEMS Product Development: From Concept to Commercialization, some highlights of which follow.

Time and money

What can MEMS startups do to pave the way for a successful commercial launch, particularly when a long period of scaling up manufacturing is often needed during the go-to-market process?

Since money is usually a limited resource, it’s important to prepare a realistic development timeline supported by sufficient funds allocation from the start. As this is easier said than done, we’ve seen both startups and established companies make common financial blunders during MEMS product development. These include:

- Reserving inadequate funding for developing the entire MEMS product, including packaging, electronics and software

- Creating an unrealistic timeline for development, resulting in a cash-flow problem

- Only securing enough funding for the first run at a foundry when, in fact, numerous runs are far more typical

- Unplanned gaps of months or more between funding tranches, which slows momentum

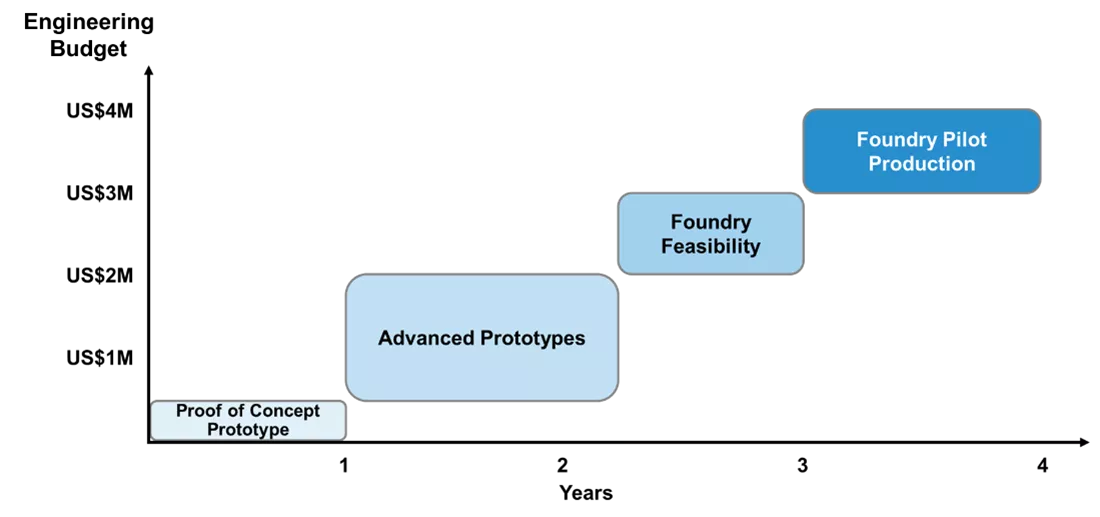

Based on our varied client experience, the engineering costs of developing a MEMS product of medium complexity to the point of validated foundry production (i.e., ready for mass production and product sales) requires on average four years and US$4 million. And that’s just for engineering. Business administration, sales, marketing and other company costs are additional. While it’s common to spend much more for more complex devices or product systems, it’s rare to spend less, unless you’re working with existing IP, such as a foundry process platform, which also could accelerate development time.

Typical engineering-only budget required to develop a MEMS product through four stages of development, to the point of volume-production readiness. Reprinted with permission from MEMS Product Development: From Concept to Commercialization (Springer, 2021).

Don’t go thirsty in the desert

No one wants to get stranded in the desert without enough water, which is why it’s so important to carefully articulate your timeline and secure adequate funding before starting MEMS development.

In MEMS development, just as in wilderness adventuring, things rarely go exactly as planned: Wafers break, engineers take a long time to debug, customers change their minds, and random events like storms (or a pandemic) disrupt supply chains. That’s why adding some buffer to your development timeline and your budget will sustain your company through the inevitable delays and setbacks.

Plus, there’s generally a ripple effect to a delayed new-product introduction. A slower-than-predicted launch places a burden on a company’s finances because the fixed overhead costs of the entire organization will continue to consume cash while waiting for product launch.

Not a lump-sum game

Although you might wish to receive one big funding check when you get started, the reality is that investors and executives won’t provide the entire development funding in one sum. They give money in tranches, generally demanding you meet some pre-determined criteria or demonstrate set benchmarks before they’ll release more funds. To best manage tranche funding, a company must carefully plan and set their investors’ expectations for realistic outcomes in advance.

A common crisis for startup companies occurs when investors only provide enough budget to execute the very first run at a foundry and then demand to see functional chips before providing the next tranche. However, the aim of the foundry’s first wafer run isn’t to produce working chips. It’s to begin the year-long process of setting up for high-volume manufacturing. The first wafers are unlikely to yield well, or at all, putting the startup at great risk with its frustrated investors.

A common crisis for startup companies occurs when investors only provide enough budget to execute the very first run at a foundry and then demand to see functional chips before providing the next tranche. However, the aim of the foundry’s first wafer run isn’t to produce working chips. It’s to begin the year-long process of setting up for high-volume manufacturing. The first wafers are unlikely to yield well, or at all, putting the startup at great risk with its frustrated investors.

Setting investors’ and executives’ expectations correctly from the start, realistic budgeting and having regular communication about progress and upcoming needs all help to keep the money flowing. Any gaps in funding will waste valuable momentum, which ultimately leads to more expense and delay in the overall product development. It can become especially damaging when the wait for money forces the foundry to stop work, because processes go stale after a few months, and also during busy times, when your product could be sent to the back of the foundry’s queue.

As experienced outdoors people know, to enjoy wilderness adventures, you need to plan where you’re going, anticipate common risks, and then prepare accordingly. It’s the same in MEMS product development. Having a good grasp of your timeline and realistic expectations about the funding required to reach commercialization are essential steps in a successful journey.

Want to learn more about MEMS Product Development: From Concept to Commercialization (Springer, 2021)? Order the book based on A.M. Fitzgerald & Associates’ extensive experience helping entrepreneurs and other innovators commercialize their MEMS devices.

Want to learn more about MEMS Product Development: From Concept to Commercialization (Springer, 2021)? Order the book based on A.M. Fitzgerald & Associates’ extensive experience helping entrepreneurs and other innovators commercialize their MEMS devices.

Alissa M. Fitzgerald, Ph.D., founded A.M. Fitzgerald & Associates, LLC, a MEMS product development firm based in the Bay Area, California, in 2003. She has over 25 years of engineering experience in MEMS design and fabrication and now advises clients on the entire cycle of MEMS product development, from business and IP strategy to supply chain and manufacturing operations.

Carolyn D. White, Ph.D., has a background in mechanics of materials and specializes in the design and fabrication of MEMS devices for a wide range of applications. She has additional experience in foundry transfers and technology strategic analysis, including of the evaluation of patent portfolios, feasibility studies, and cost/performance analysis.

A.M. Fitzgerald & Associates (“AMFitzgerald”) is longtime member of MEMS & Sensors Industry Group®(MSIG), a SEMI technology community that connects the MEMS and sensors supply network in established and emerging markets to enable members to grow and prosper. Visit us today.