On Saturday, March, 21, 2020 the U.S. Food and Drug Administration (FDA) gave emergency authorization to Cepheid, a California company, to sell a new test for rapid detection of the pandemic coronavirus SARS-CoV-2, which causes COVID-19. Cepheid’s Xpert® Xpress SARS-CoV-2 test gives healthcare workers results in just 45 minutes, with less than a minute of hands-on time for sample preparation.

Cepheid, founded by Kurt Petersen, M. Allen Northrup and five others in 1996, is well known in the MEMS community for commercializing microfluidic chip-based polymerase chain reaction (PCR) analysis machines. This is not the first time Cepheid has responded quickly to a biological threat; after the 2001 terrorist attacks in the USA, Cepheid was the first to provide rapid anthrax detection capabilities to the U.S. Postal Service, and it still does today.

At the heart of all COVID-19 test protocols (see the WHO protocol and U.S. CDC protocol) is the real-time reverse transcription polymerase chain reaction (RT-PCR) analysis technique. In a very simplified description, PCR uses thermal cycling to amplify the DNA present in a patient’s swab sample, and then using fluorescence optical detection, searches for the virus’s specific DNA. The test requires knowing the virus’s genome in the first place; the crucial work to sequence the full genome of SARS-CoV-2 was first published by Chinese scientists for public use on January 10, 2020.

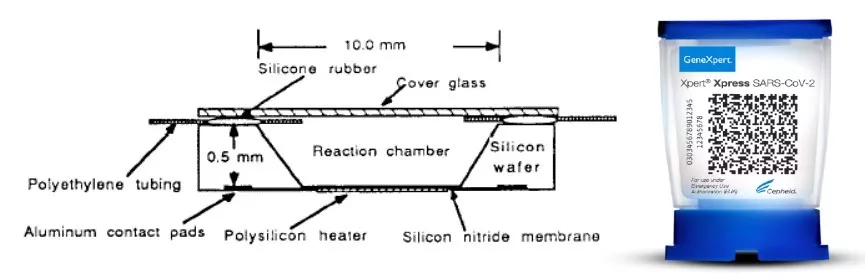

While traditional PCR machines take many hours to thermal cycle and reach a result, MEMS-based PCR systems can work much faster. Featuring scale heaters and reaction chambers that have a tiny thermal mass, they create a significantly faster heat-cool cycle, enabling a rapid result in minutes.

The first MEMS silicon PCR chip, developed by Northrup et. al. at Lawrence Livermore National Laboratory and licensed to Cepheid (left) and the Cepheid test cartridge today (right). (Source: Northrup MA, Ching MT, White RM, Watson RT, “DNA amplification in a microfabricated reaction chamber,” Transducers 1993, Yokohama, Japan. pp. 924–926.)

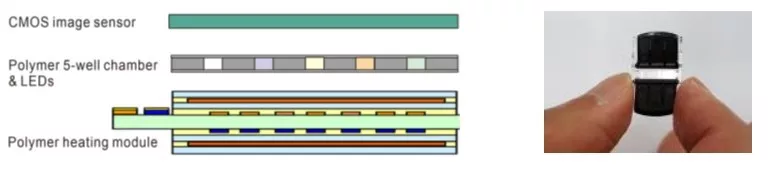

Research on MEMS-based PCR systems has continued steadily since the early 1990s. Today, researchers have been focusing on developing highly integrated, low-cost systems specifically for point-of-care use. One example of recent research: a team at Korea’s ETRI and Genesystem have developed a prototype low-cost, handheld PCR system having a polyimide chamber and microheater and an integrated CMOS detector for optical readout of results (figure below).

Cross-section schematic of the chamber, heating module and integrated optical detector in a portable PCR prototype (left) and integrated test cartridge (right). (Source: DS Lee, OR Choi, and YJ Seo, “A Handheld and Battery-Powered Realtime Microfluidic PCR Amplification Device,” Transducers 2019, Berlin, Germany pp. 1063-1065.)

Korea’s quick recruitment of its biotech companies and creation of novel drive-through testing sites helped it to successfully pinpoint its COVID-19 outbreak and to implement control measures. Let’s hope the Cepheid test can be similarly effective.

Based on successive epidemics of SARS, MERS and now COVID-19, rapid PCR test machines, enabled by MEMS technology, are becoming essential medical tools in the fight against viral outbreaks. As continued development lowers the cost of such critical equipment, let’s hope we may soon have a PCR machine in every doctor’s office.

Alissa M. Fitzgerald, Ph.D., founded A.M. Fitzgerald & Associates, LLC (“AMFitzgerald”), a MEMS and sensors solutions company based in Burlingame, CA, in 2003. She has over 25 years of engineering experience in MEMS design, fabrication and product development.

Alissa M. Fitzgerald, Ph.D., founded A.M. Fitzgerald & Associates, LLC (“AMFitzgerald”), a MEMS and sensors solutions company based in Burlingame, CA, in 2003. She has over 25 years of engineering experience in MEMS design, fabrication and product development.

Prior to founding AMFitzgerald, Fitzgerald worked at the Jet Propulsion Laboratory, Orbital Sciences Corporation, Sigpro, and Sensant Corporation, now part of Siemens. She received her bachelor’s and master’s degrees from MIT and her doctorate from Stanford University, in Aeronautics and Astronautics. Fitzgerald has numerous journal publications and holds eight patents. She served on the Governing Council of MEMS Industry Group from 2008-2014 and was inducted into the MIG Hall of Fame in 2013. Fitzgerald serves on the Board of Directors of both Rigetti Computing and the Transducer Research Foundation.

AMFitzgerald is a longtime member of MEMS & Sensors Industry Group (MSIG), a SEMI Strategic Association Partner. For more information on AMFitzgerald, please visit: https://www.amfitzgerald.com.

Interested in learning more about this topic? Read Alissa M. Fitzgerald and Farzad Khademolhosseini’s article in EE Times, MEMS in the Fight Against Covid-19.