Part 1 of this two-part piece explores best-practice perspectives on collecting and utilizing smart data in industries outside semiconductor manufacturing, one of the important takeaways from the Smart Manufacturing panel discussion at SEMI ASMC 2018.

Part 2 examines the potential benefits to be realized by pairing human Subject Matter Experts with smart silicon assistants, and what these new arrangements mean for semiconductor device manufacturing.

The spacecraft Discovery and its HAL 9000 computer system had a digital twin.

Did you know?

Stanley Kubrick’s seminal film “2001: A Space Odyssey” had its theatrical release 50 years ago this April. “2001” isn’t just a great science fiction film. Rather, it’s a great work of cinema overall, across any category. (The American Film Institute lists “2001” as #15 in the AFI Top 100; a bit below “Vertigo,” a bit above “It’s A Wonderful Life.”)

It’s a film so distinguished and so prescient that its lessons can inform our thinking about smart manufacturing, Industry 4.0, and artificial intelligence (AI) today.

Not to give too much away, but the earth-bound digital twin of Discovery / HAL identifies a diagnostic error the onboard, Jupiter-bound HAL 9000 has made, things go awry from there, and one of the mission pilots, astronaut Dave Bowman, is forced to intervene.

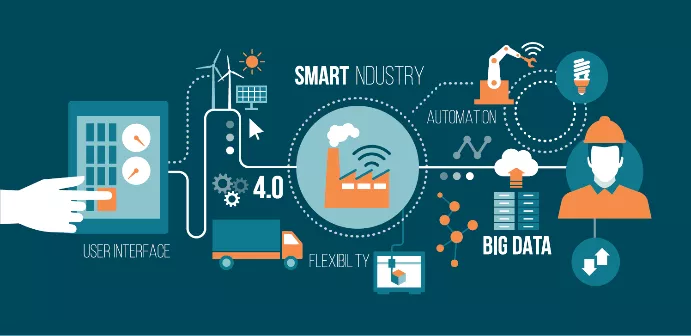

At the recent SEMI Advanced Semiconductor Manufacturing Conference, ASMC 2018, on 02 May 2018 in Saratoga Springs, NY, five diverse panelists representing capital equipment, IDMs, academia, the semiconductor supply chain, and smart manufacturing best practices outside the semiconductor industry engaged in a lively discussion with the ASMC attendees. They explored where “smart” is in our industry today, where it’s headed, and what that’s going to mean for us -- the professionals who have brought semiconductor manufacturing to the current state of smart, and are looking to implement an ever-smarter tomorrow.

Not to give too much away, but the panelists and audience agreed that there’s nothing artificial about pairing human intelligence with machine-based smart manufacturing. Implementing an ever-smarter tomorrow in semiconductor manufacturing requires smart people just as much as it requires smart machines.

Moving towards “smart” means understanding how to derive useful information and actionable intelligence from the ever-increasing pool of big data created during semiconductor manufacturing. Modern manufacturing sites are extensively instrumented today, and create massive amounts of data to consume, decipher, base decisions upon, or discard.

As we dig into this problem we realize that equipment and processes in our industry are both obviously complex, but, also, subtly complex. Semiconductor manufacturing tools easily contain 100s to 1000s of components working together to produce nanometer scale, angstrom scale, or even atomic scale features using complex chemical, physical, and plasma processes. There is a plethora of potential failure points and modes, and despite our best efforts to collect more data, many processes continue to be only poorly observable. On top of that, semiconductor fabrication processes are always drifting, and the operational context is continually changing as we change product mix, process maintenance swap-out kit components, and operating conditions and recipes.

Sounds like … hospitals, and healthcare?

When you see your doctor, she will collect and look at your instrumented data – blood work, blood pressure, weight, and other quantifiable factors. But, typically, your doctor won’t draw a conclusion based on that analysis alone. Rather, your doctor will sit with you, ask probing questions, and record what she asked, your responses, and what she saw, what she heard, and what she thought. Then she’ll build a hypothesis, combining the “anecdotal” data with the instrumented data, and derive from that data set both a likely diagnosis and an effective course of action.

In this case, beyond the instrumented data, two humans, and their natural language input, are part of the equation: the patient, with his observations and thoughts, as well as the doctor, with hers. And it’s been a formula for success. Healthcare has made huge, step-function improvements across a spectrum of deadly diseases, as well as with less-deadly chronic afflictions, by harvesting this complex input, committing the proven disease presentation – disease diagnosis – and disease treatment models to medicine’s collective memory, and then teaching the next generation of healthcare providers both the general methods and the standard protocols essential to maintaining good health and successful outcomes.

Maybe, in medicine, what seems a big data environment is really just clusters and clusters of loose small data connected by the collective neural network of highly trained doctors and their colleagues.

Nancy Greco (IBM Watson), Dave Mayewski (Rockwell Automation), James Moyne (University of Michigan / Applied Materials), and Paul Werbaneth (Intevac, Inc.), along with Julie Jacob (Ernst & Young), and Carson Henry (Micron Technology), were members of the SEMI ASMC 2018 panel discussing Industry 4.0 and the Future of Commercial Semiconductor Device Manufacturing. All opinions here are purely our own. Please contact Paul Werbaneth via email at pwerbaneth@intevac.com.

The SEMICON West (July 9-11, 2018, in San Francisco) Smart Manufacturing Pavilion features working production equipment on the floor and three full days of speakers providing insights on building the infrastructure needed to enable AI.

Equipment from Bosch Rexroth, Cimetrix, Rudolph Technologies, INFICON, Final Phase Systems, OMRON, DISCO and Edwards Vacuum will showcase cutting-edge smart manufacturing technologies.

For information on the SEMI Smart Manufacturing initiative and how to get involved, please click here.