I recently spoke with Andrew Goh, Vice President at General Manager at Lam Research Southeast Asia, about the importance of the company's new production facility in Penang and its COVID-19 relief efforts.

Ng: Before we delve into details, please provide a quick introduction to Lam Research Southeast Asia for our readers who aren't as familiar with your work.

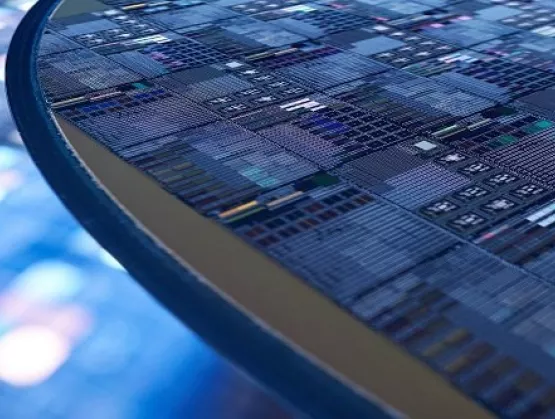

Goh: As you know, Lam Research is a leading supplier of wafer fabrication equipment and services to the global semiconductor industry. Since we were established in 1980, Lam has played a key role in contributing to the extraordinary pace of innovation in the semiconductor industry. We have always developed innovative solutions that help our customers build smaller, faster, more powerful, and more power-efficient electronic devices – the kind that are driving the proliferation of technology in our everyday lives.

Further to this, we established Lam Research Southeast Asia in 1992 to better serve our customers in this region. We have about 260 employees in both Malaysia and Singapore, with more than two-thirds of them in engineering or technical roles.

Ng: Early this year, Lam Research announced a new advanced technology production facility in Malaysia. Please tell us about it.

Goh: Yes, Lam Research and the Malaysian Investment Development Authority jointly announced in February 2020 that Lam selected Batu Kawan Industrial Park in Penang, Malaysia as the location for a new advanced technology production facility.

Goh: Yes, Lam Research and the Malaysian Investment Development Authority jointly announced in February 2020 that Lam selected Batu Kawan Industrial Park in Penang, Malaysia as the location for a new advanced technology production facility.

Our new state-of-the-art manufacturing site in Penang’s Batu Kawan will open in May 2021 and be the largest in our network. The current plan envisions a 700,000 square-foot facility with expansions already anticipated to serve current and future customers. Construction started in May 2020, and we aim to have our first shipment by 2021. We are currently at our temporary site in Bayan Lepas.

Ng: As Lam’s manufacturing site, what role does it play in the larger organisation?

Goh: The semiconductor industry is expanding and so are we. To help our customers move the world forward, we need a dynamic, energized team with initiative and focus to help establish our footprint in Malaysia. This has led to the expansion of our existing global production footprint with locations in the United States, South Korea, and Austria.

As the industry moves forward, we at Lam Manufacturing Malaysia will work on the entire portfolio of our leading-edge products, collaborating closely with customers to create some of the world’s most sophisticated processes and fabrication equipment. We chose Penang for its talented workforce with experience in aerospace, health sciences manufacturing and other high-tech fields.

We are currently hiring now for our site in Penang. Anyone interested in exploring job opportunities at the site can send learn more and apply at www.MakeAtLamPenang.com.

Artist's rendering of new Lam Research production facility at the Batu Kawan Industrial Park in Penang.

Ng: With the world now thrown into an unprecedented situation, do you expect any delay in the construction schedule?

Goh: Despite the COVID-19 pandemic, construction began in May 2020. We still expect to make our first shipment from the Batu Kawan factory around mid 2021, in line with our initial estimates. Close cooperation with and timely support from MIDA and Invest Penang have allowed us to stay on track.

Ng: How has Lam done supported COVID-19 relief or recovery efforts during this pandemic?

Goh: Just as with any other business, this pandemic indeed is a trying time for all of us around the world. We announced on April 8 that we are donating $25 million to global COVID-19 relief and recovery efforts, which includes relief funds to employees, employee benefit resources, and additional support for the areas in which we operate. This support includes supplies for hospitals, both short-term and long-term community assistance, and our 2-for-1 gift matching for eligible COVID-19 relief programmes.

In addition to the fund, we have also donated our surplus inventory of masks for immediate relief to local hospitals. At the same time, our innovative engineers and others with 3D printers at home have begun developing prototypes and printing protective face shields.

In addition to the fund, we have also donated our surplus inventory of masks for immediate relief to local hospitals. At the same time, our innovative engineers and others with 3D printers at home have begun developing prototypes and printing protective face shields.

Consistent with current guidance from the U.S. as well as the region’s respective Centers for Disease Control (CDC) and World Health Organization (WHO), we have activated our business continuity plan (BCP) to safeguard the health and well-being of our employees and their families, as well as to mitigate business disruptions to our customers. Measures we've implemented include strict social distancing, quarantine measures and travel restrictions.

Bee Bee Ng is president of SEMI Southeast Asia.