SEMI Launches Successful 2017FLEX Japan

By Mike Ciesinski, CEO, FlexTech | SEMI Strategic Association Partner

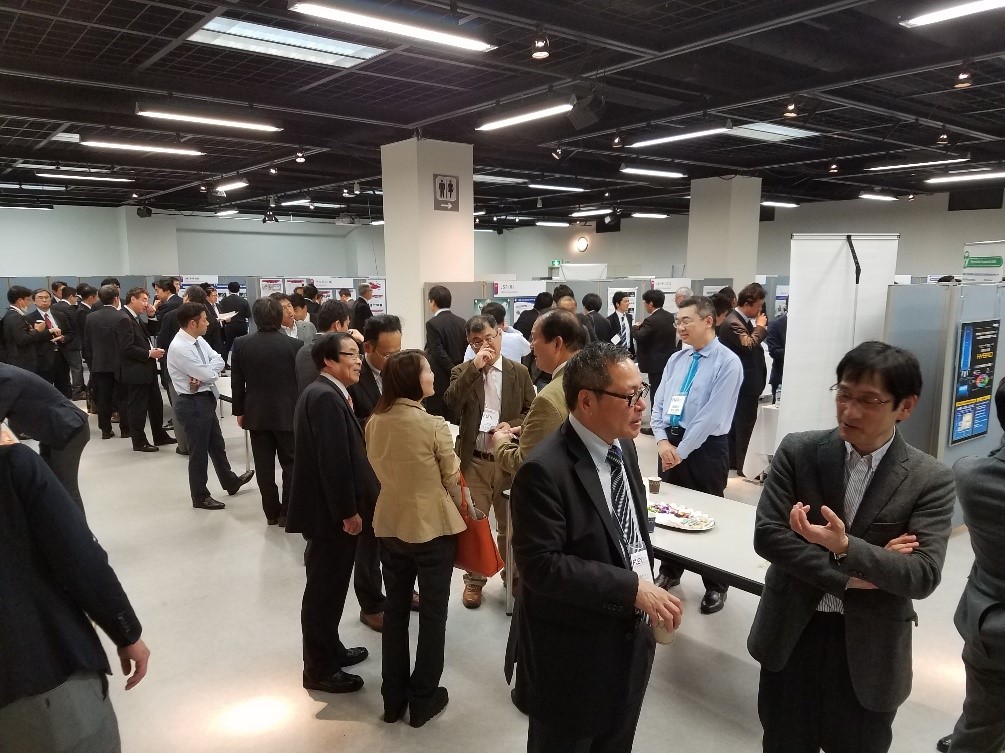

The inaugural FLEX Japan opened at Kokuyo Hall in Shinagawa, Japan, on Tuesday, April 11, 2017 to a sold out audience of more than 250 scientists, engineers and business development professionals. The program, comprised of 17 speakers drawn from Japan and the international flexible electronics community, addressed flexible electronics, IoT, MEMs and sensors, and smart textiles. FLEX Japan featured an exhibit hall of 23 companies including ACHILLES, SPP Technologies, JSR, SHINKO ELECTRIC INDUSTRIES, SCREEN, Sumitomo Chemical, TAIYO INK, Disco, DuPont K.K., TOKYO SEIMITSU, Toshiba Nanoanalysis, TOYOBO, Toray Engineering, NAGASE, HISOL, HORIBA STEC, Hitachi Chemical, Hitachi High-Technologies, Murata Machinery, Merck Performance Materials, Yamanashi Thin Film Technology Developments, YUASA System and Lasertec.

The inaugural FLEX Japan opened at Kokuyo Hall in Shinagawa, Japan, on Tuesday, April 11, 2017 to a sold out audience of more than 250 scientists, engineers and business development professionals. The program, comprised of 17 speakers drawn from Japan and the international flexible electronics community, addressed flexible electronics, IoT, MEMs and sensors, and smart textiles. FLEX Japan featured an exhibit hall of 23 companies including ACHILLES, SPP Technologies, JSR, SHINKO ELECTRIC INDUSTRIES, SCREEN, Sumitomo Chemical, TAIYO INK, Disco, DuPont K.K., TOKYO SEIMITSU, Toshiba Nanoanalysis, TOYOBO, Toray Engineering, NAGASE, HISOL, HORIBA STEC, Hitachi Chemical, Hitachi High-Technologies, Murata Machinery, Merck Performance Materials, Yamanashi Thin Film Technology Developments, YUASA System and Lasertec.

Dr. Melissa Grupen-Shemansky, SEMI’s CTO for Flexible Electronics and Advanced Packaging, provided the opening keynote on flexible hybrid electronics (FHE). She explained that the convergence of wearable connected devices and personal communication devices presents a new opportunity for electronics products. Essentially, FHE can monitor and report on everything from human performance through structural monitoring to asset tracking. Manufacturing of these devices combines the best, most innovative aspects of traditional silicon IC processes and graphic printing.

The Air Force Research Laboratory (AFRL) presentation on flexible electronics and batteries was delivered by Dr. Michael Durstock. He reviewed the Air Force’s interest in FHE, which are advancements to human performance assessment, lower weight electronics, agile manufacturing, and survivability. The AFRL scientist described a printable composite electrode leading to printed batteries. AFRL was followed by Toshihide Kamata from the National Institute of Advanced Industrial and Science Technology (AIST), who commented that FHE is an enabling technology for the Internet of Things (IoT) devices.

Several presentations focused on the application of FHE technology. For example, Helen Kardan of the Holst Center/TNO stated that the center’s FHE R&D is concentrated in the automotive industry, specifically smart surfaces, and in the medical devices industry. For medical devices, Holst believes that power + comfort + data accuracy + a disposable patch are the key ingredients for a successful application.

Several presentations focused on the application of FHE technology. For example, Helen Kardan of the Holst Center/TNO stated that the center’s FHE R&D is concentrated in the automotive industry, specifically smart surfaces, and in the medical devices industry. For medical devices, Holst believes that power + comfort + data accuracy + a disposable patch are the key ingredients for a successful application.

Samsung’s R&D on printed electronics is focused on bio-sensors and flexible IoT devices, according to Yong Uk Lee, research staff member. He disclosed a national project in Korea, the Printed Electronics Total Solutions program (PETS), which targets printed OLED lighting, digital signage and active wallpaper. PETS has $126M budget and 31 members.

2017FLEX Japan concluded Day 1 with an industry reception within the exhibit hall.

Day 2 of the 2017FLEX Japan focused on MEMS markets and technology and the many approaches to electronic textiles. A wide-ranging review of technologies which have a substantial impact on the success of IoT and next-generation technologies making it possible.

Dr. Masayoshi Esashi, Professor, Micro System Integration Center, Tohoku University provided an excellent overview of MEMS developments, noting that bottlenecks have always come in determining how to manufacture and production efficiencies. There has been much work on MEMS and the development of the technology continues apace. MEMS has quickly gotten quite complicated, aided by deep reactive ion etch which has enabled some huge leaps in capabilities and productivity.

Dr. Masayoshi Esashi, Professor, Micro System Integration Center, Tohoku University provided an excellent overview of MEMS developments, noting that bottlenecks have always come in determining how to manufacture and production efficiencies. There has been much work on MEMS and the development of the technology continues apace. MEMS has quickly gotten quite complicated, aided by deep reactive ion etch which has enabled some huge leaps in capabilities and productivity.

Yu-Ching Lin, assistant director at the Japan Research Center for Goerteck Technology Japan, called for less competition among consumer electronics products in terms of their intelligent connections, so that standardization could move more quickly and products would not be kept in silos of by their software systems. She discussed how MEMS sensors are mimicking human senses drawing parallels and concluding that machine decisions, based on these MEMS sensors are becoming more commonplace.

Takeshi Kobayashi from the National Institute of Advanced Industrial Science and Technology (AIST) and Koutsuke Suzuki from Dai Nippon Printing presented on a joint project in creating strain sensor arrays aimed at detecting bridge fatigue and other road stresses. The ultra-thin Si/FPC substrate with advance film packaging has been put through an extensive testing cycles required by strong building code requirements for public infrastructure. DN Printing felt that with their current business model incorporating the collection and manipulation of big data they stood in good place to capitalize on these new products.

The afternoon talks comprised a thorough review of electronic textile approaches, including foldable textile electronics and Google’s latest Jacquard approach from Dr. Mutsumi Kimura, Faculty of Textile Science and Technology, Shinshu University.

The afternoon talks comprised a thorough review of electronic textile approaches, including foldable textile electronics and Google’s latest Jacquard approach from Dr. Mutsumi Kimura, Faculty of Textile Science and Technology, Shinshu University.

“This first FLEX Japan was an unqualified success with excellent technical program content and congenial networking at the product exhibits. FLEX Japan will now play a vital role in the FHE industry’s development, fostering collaboration between the strong Japanese community and global players,” said Michael Ciesinski, president of SEMI’s FlexTech Group.

For more information, contact Heidi Hoffman, Senior Director for FHE, MEMS and Sensors Marketing, SEMI at hhoffman@semi.org or SEMI Japan at jcustomer@semi.org.

April 12, 2017