Introduction to SEMI's Communication Standards: SECS/GEM

By Mitsune SAKAMOTO, Zama Consulting

Introduction

SEMI's communication standards, SECS/GEM, has been around for nearly 30 years since its publication, and GEM300 has been around for over 20 years as the basis for automated specifications in semiconductor manufacturing. These standards are still valid for semiconductor manufacturing lines and should be applied to their automation. Therefore, it is necessary to maintain human resources capable of understanding and using these SEMI communication standards and continue to provide support for the automated operation of semiconductor manufacturing. To support these needs, SEMI has held the SECS/GEM and GEM300 communication standard seminars every year.

Unfortunately, seminars in people attendance have been canceled due to the impact of the novel coronavirus since 2020. In that situation, thanks to the efforts of the SEMI Secretariat and volunteer instructors, we have started a series of seminars via webinar in 2021. In 2022 again, we are going to offer a series of webinars with updated and improved content.

This article provides an overview of what SECS/GEM and GEM300 are, and introduces them to the SEMI Communications Standard, for those of you who are starting SECS/GEM and GEM300.

Purpose of Making Semiconductor Manufacturing Equipment Online

The purpose of the Online operation of semiconductor manufacturing equipment is to manage the equipment and automate its operation in collaboration with the factory information system.

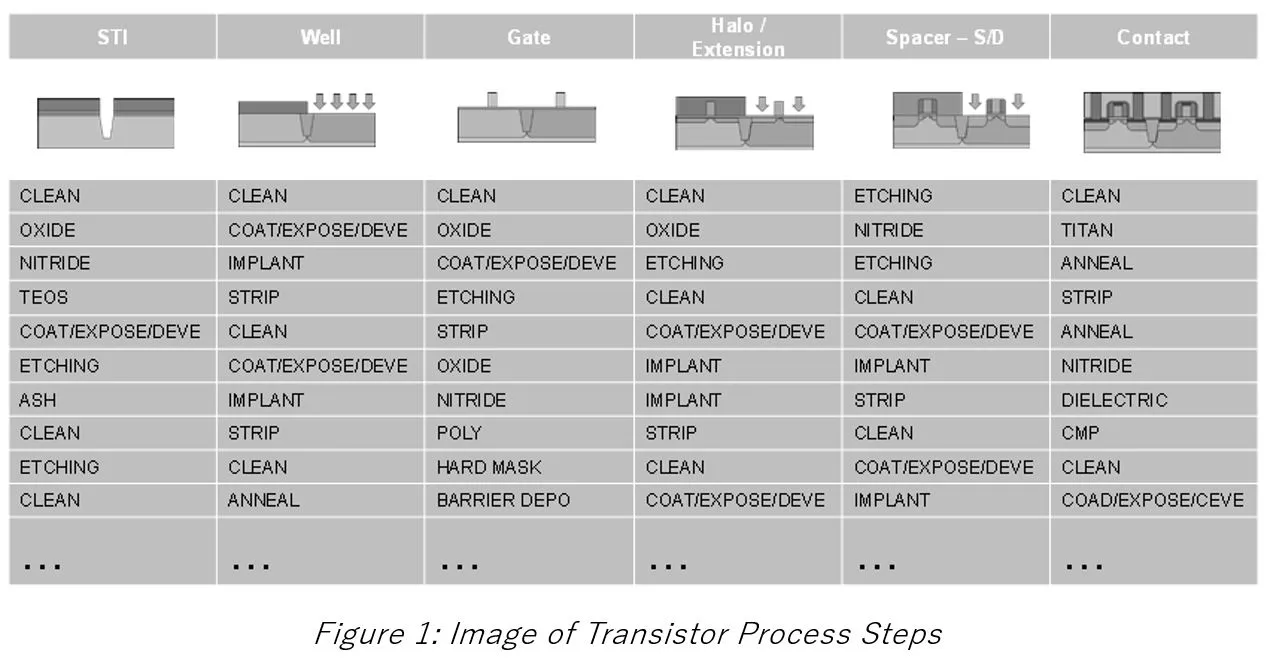

The reason why we should bring equipment online is that semiconductor manufacturing involves many process steps and is complicated to manage and control. Figure 1 shows an image of the process steps for forming transistors on a wafer. There are more than 100 process steps throughout from STI, Well to Contact, and a series of process steps must be executed at the right time for each wafer by process steps. In addition, the equipment must be operated with appropriate processing conditions specified for each process step. The only way to manage and operate these equipment without fail nor delay is with the help of IT technology. Semiconductor manufacturing equipment must be integrated with systems that manage and control production (factory information systems, or hosts) via communications.

Online Operation of Semiconductor Manufacturing Equipment

The equipment used for each process step should be online for interaction with the host. The online semiconductor manufacturing equipment reports the status of the equipment to the factory information system, receives commands from the system, and performs operations. This allows the factory information system to monitor the status of the equipment and remotely control its operation.

For example, when a device reports that “a wafer to be processed has arrived”, “a wafer process has started”, “a wafer process has finished”, or “a processed wafer has been shipped”, the host (factory information system) captures those events and proceeds with the process step. The host specifies the process conditions for the arriving wafer to the equipment and instructs to start the process. The process steps intended by the factory information system are now executed sequentially by the equipment.

Standardization of Communication Between Host and Equipment

In order to connect semiconductor manufacturing equipment online, the equipment must be able to communicate with the host for the automation.

Various equipment are used in the semiconductor manufacturing line, and the functions required vary depending on the structure and behavior of each equipment. There are many process steps in semiconductor manufacturing, and it is difficult to define and manage the communication method (specification) of the equipment corresponding to each step individually because the number of specifications becomes enormous. Standardization of communication is required.

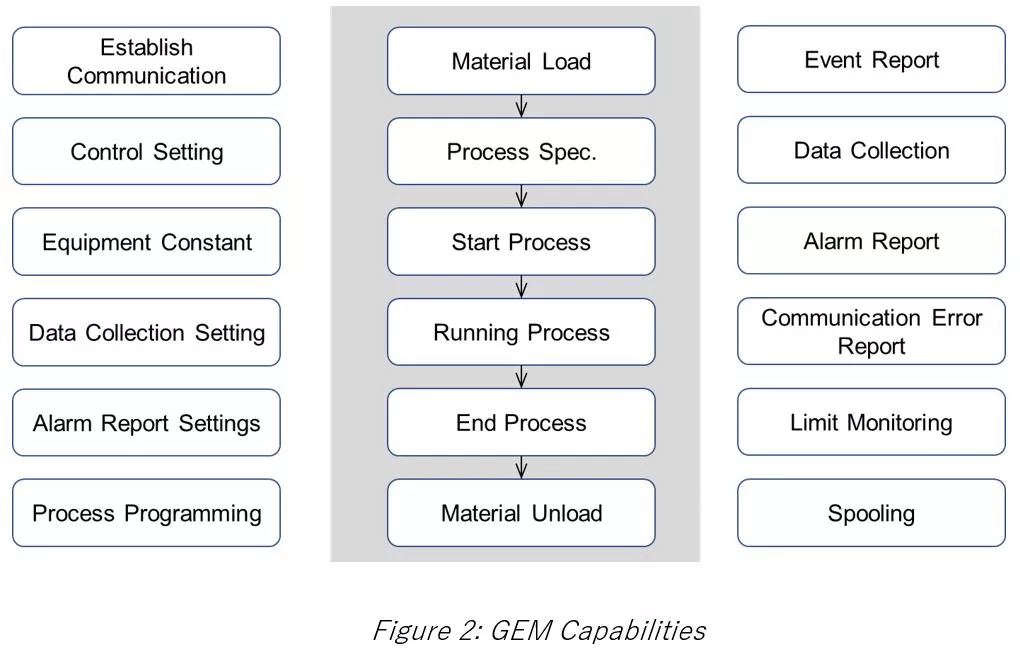

In order to standardize the communications, it is necessary to model the communications functions that should be shared by all semiconductor manufacturing equipment. That model is represented by the so-called Generic Equipment Model (GEM). Figure 2 shows a functional model of applied to the management and automation of semiconductor manufacturing equipment. The central row in this diagram models the main task of the semiconductor manufacturing equipment. Materials (wafers) are loaded, process conditions are specified, processes are executed, and finally materials are unloaded. In addition, we need to model various functions to support the "main task" area. The left column in the figure shows models for the functions which configure communication and other settings before running the process, and the right column shows a set of functional models for such as data reporting.

SEMI E30 (GEM)

The GEM "Generic Equipment Model" has been published as a standard represented by the designation SEMI E30. The official name of SEMI E30 is SPECIFICATION FOR THE GENERIC MODEL FOR COMMUNICATIONS AND CONTROL OF MANUFACTURING EQUIPMENT (GEM).

SEMI E5 (SECS-II)

The SEMI E30 (GEM) defines a communication model for semiconductor manufacturing equipment but does not define the details of the messages exchanged in that communications. The messages are defined by SEMI E5 (SECS-II). The official name of SEMI E5 is SPECIFICATION FOR SEMI EQUIPMENT COMMUNICATIONS STANDARD 2 MESSAGE CONTENT (SECS-II).

SECS-II has collected detailed definitions of various messages used for communications in semiconductor manufacturing equipment since the 1980’s. SEMI E30 was developed in the 1990’s to define how the messages defined in SECS-II are applied to the "generic equipment model". So, you need to know the SECS-II messages to apply the SEMI E30 (GEM).

SEMI E37 (HSMS)

The details of the message were determined in SECS-II. However, SECS-II does not define how to deliver the messages. The SECS-I and HSMS specifications are used to communicate SECS-II messages to the other party. SECS-I uses serial communication. HSMS, meanwhile, uses TCP/IP. SECS-I was established in the 1980’s and is rarely used at the current host-equipment communications. Currently, almost all semiconductor manufacturing lines use HSMS. This is because TCP/IP makes it easy to connect to the network. HSMS specifications are specified in SEMI E37.1. The official name of SEMI E37.1 is SPECIFICATION FOR HIGH SPEED SECS MESSAGE SERVICE SINGLE SELECTED-SESSION MODE (HSMS-SS).

Transition to 300 mm

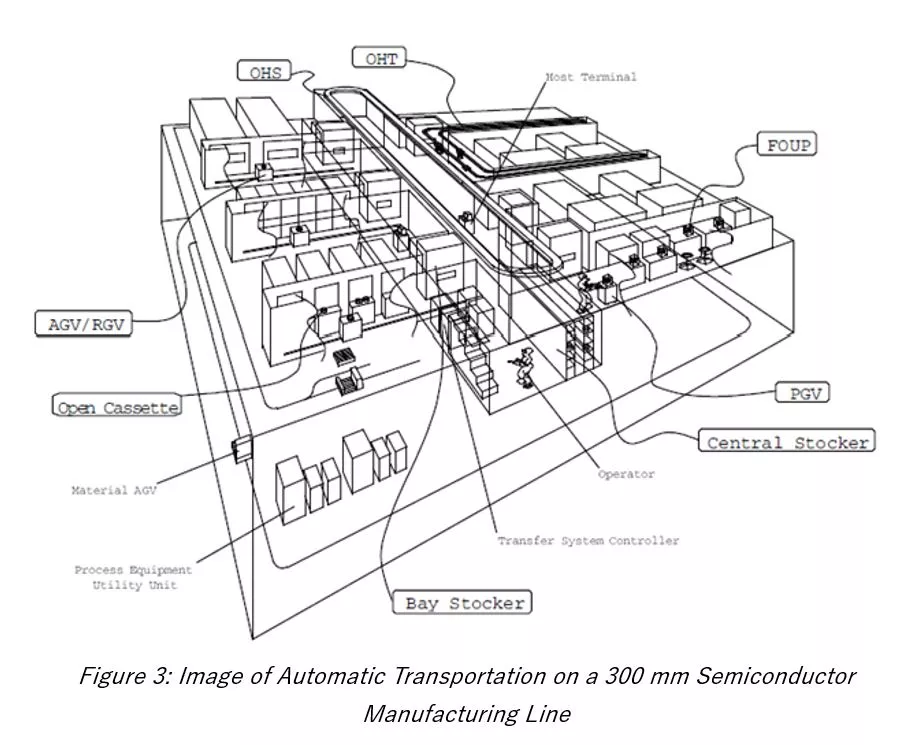

Since 2000, the introduction of 300 mm wafers has renewed the basic technology for semiconductor manufacturing, further advancing standardization. An important standardization at this point was the decision to use the FOUP (Front Opening Unified Pod) as a wafer carrier, and the design of the carrier load port. In addition, it became premised on the use of automatic carrier transport to carry heavy 300 mm carriers.

In terms of automation of equipment operation, a standard was added to eliminate variations in operation prior to the introduction of 300 mm. For example, the standardization of checking method for carrier (FOUP) ID is worthy to mention.

GEM300

GEM300 is a set of standards that define the general equipment models used in 300 mm manufacturing lines. Since it is a "standard group", multiple standards are defined in it. Table 1 summarizes the GEM300 standards. These standards specify specifications for each function applicable to the automatic operation of 300 mm devices.

Table 1 GEM300 Key Standards

|

Standard Designation |

Title |

Feature |

|---|---|---|

|

SPECIFICATION FOR PROCESSING MANAGEMENT |

Specifications for managing and controlling wafer processing conditions (recipes) and process execution |

|

|

SPECIFICATION FOR CARRIER MANAGEMENT (CMS) |

Specifications for managing and controlling for loading and unloading carriers |

|

|

SPECIFICATION FOR SUBSTRATE TRACKING |

Specification for reporting wafer information within the device |

|

|

SPECIFICATION FOR CONTROL JOB MANAGEMENT |

Specifications for managing and controlling carrier-based processing in response to semiconductor manufacturing process steps |

Summary

We need IT to ensure that process steps are executed consistently.

Communication is required to link manufacturing equipment with IT.

SEMI Standard specifies the general device model and its communication standard.

The general device model has evolved into a 300 mm management and control specification.

SEMI Standards are the basic specification for automation of today's semiconductor manufacturing lines.

SEMI Software Standard SECS/GEM Seminar

SEMI Software Standard "GEM300" Seminar

If you would like to participate in the SEMI Standards Information & Control Global Technical Committee standardization activities, please contact: Mami Nakajo, SEMI Japan Standards & EHS Department at jstandards@semi.org.

Get Involved

SEMI Standards development activities take place throughout the year in all major manufacturing regions. To get involved, join the SEMI International Standards Program at: www.semi.org/standardsmembership.

For more information, please visit our main Web site and current events page. If you have any questions regarding SEMI Standards activities, please contact your local SEMI Standards staff.

Standards Watch

SEMI

www.semi.org

September 1, 2022