As predicted by Moore’s Law, the semiconductor field has been growing at a steady pace since the 1960s. In parallel with this progression, semiconductors became cheaper and easier to produce — until they weren’t. At today’s bleeding edge, semiconductors are far more complex and densely integrated, which is making them more challenging to manufacture and, therefore, more expensive. While such advancements pose new challenges to semiconductor manufacturing, we can extend Moore’s Law well into the future by reimagining the semiconductor manufacturing process.

Fortunately, we have the technologies we need to shift our approach. The strategic integration of data analytics, machine learning and AI into semiconductor manufacturing will fuel our ability to keep pace with the market for many years to come.

But the availability of these technologies isn’t the same as implementing a new paradigm. That’s because realizing this level of change within such a large and diverse industry requires collaboration.

Moving Beyond Silos

The various stages of the semiconductor lifecycle — design, fabrication and testing — have traditionally operated in silos, with limited sharing of information. Instead of directly sharing raw data and real results with one another, technical staff have abstracted the information into specification sheets.

For example, a chip designer may have simulated their original design in detail. Instead of directly sharing the simulation results with other stakeholders, however, they’ll conventionally distill that information into a specification sheet — which is the only information shared down the line.

![]() And that’s problematic because specification sheets don’t capture the fine particulars, often obscuring vital information. Because this lack of transparency conceals important details, the semiconductor industry has been unable to fully optimize designs and processes.

And that’s problematic because specification sheets don’t capture the fine particulars, often obscuring vital information. Because this lack of transparency conceals important details, the semiconductor industry has been unable to fully optimize designs and processes.

Yet there is a way to assure high yields, despite the complexity and expense of testing next-generation semiconductors. The key lies in incorporating comprehensive test and analytics solutions, both before and during the high-volume manufacturing process.

The Role of Data Standards

In many ways, semiconductor test is a finely tuned process involving the production of enormous amounts of data. And these data can be used by downstream systems, such as data analytics platforms. However, the format in which one company's test platform outputs data may be incompatible with other data analytics systems. This incompatibility can create the need for custom development when integrating and analyzing data across different platforms, slowing the time to enact meaningful learnings.

Today, the most commonly used data format in test and manufacture, Standard Test Data Format (STDF) — a binary format that needs to be translated to ASCII — is problematic on two levels: It’s often applied inconsistently and it can’t handle different data sources. And if an engineer wants to add extra test data? It gets even worse. The engineer must dump the test data in the Generic Data Record (GDR), which they then must manually interpret after the test is complete. Data analytics companies for the semiconductor industry have emerged to help clean the data, pull it together and glean the related useful information.

It's easy to see how the inability to utilize data among different systems hinders the efficiency of data analysis, ultimately affecting learnings throughout the semiconductor design and manufacturing process. This one important aspect of managing data from the semiconductor test process can slow the pace of innovation in the semiconductor industry.

Change is Underway

Fortunately, change is already underway. SEMI’s Smart Data-AI Initiative exemplifies a new approach to industry collaboration as it aims to provide a framework for sharing data among different functions within a fab.

“The global semiconductor industry is projected to reach $1 trillion by 2030, according to a 2022 report from McKinsey & Company, but this will not happen on auto-pilot,” said Dr. Pushkar Apte, Strategic Technical Advisor at SEMI. “To accomplish this, we will need to continue the pace of innovation to make billions of increasingly complex microelectronic devices — all of which must be tested for performance, reliability and other metrics before they reach their target application.

“If we are to maintain high performance and quality on such a massive scale, we need to embrace the strategic integration of data analytics, machine learning and AI in semiconductor manufacturing processes,” Apte said. “The SEMI Smart Data-AI Initiative is a platform that drives value-creation from data and AI that are specific to the semiconductor ecosystem. The initiative enables pre-competitive collaboration through the entire ecosystem to accelerate innovation while preserving the integrity of an individual company’s IP.”

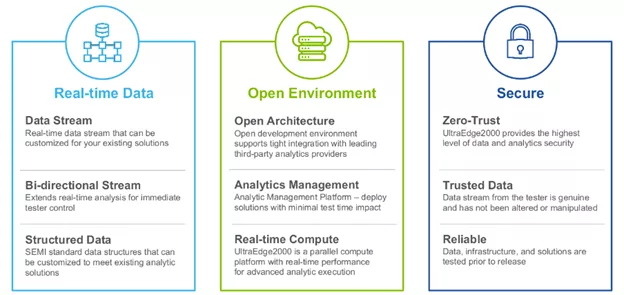

As a member of the SEMI Smart Data-AI Initiative, Teradyne is working toward standardizing test data outputs, an adjustment that encourages collaboration without fear of IP exposure or vendor lock-in. With this in mind, we designed the Teradyne Archimedes analytics solution, an open development environment that delivers access to real-time testing data.

Teradyne Archimedes Analytics solution employs an open architecture to support a vendor-agnostic analytics strategy. Source: Teradyne.

Teradyne customers can now easily integrate off-the-shelf data analytics solutions from third-party companies with our testers. And because our architecture is agnostic, customers can also use the same platform with their home-grown analytics solutions. The choice is theirs.

Beyond Moore’s Law

Moore's Law is decelerating, but that doesn't necessitate a slowdown in semiconductor advancements. Collaboration among industry stakeholders may be instrumental in continuing the demanding pace of Moore’s Law for years to come. Integrating data analytics, ML and AI into semiconductor test processes is an important step in realizing this goal.

About the Author

Dr. Jeorge S. Hurtarte, senior director of SOC product strategy and principal marketing strategist at Teradyne, has more than 35 years of experience in the semiconductor industry and has held various technical, management and executive positions at Teradyne, Lam Research, LitePoint, TranSwitch and Rockwell Semiconductors. He is currently a member of the SEMI North America Advisory Board.

Dr. Jeorge S. Hurtarte, senior director of SOC product strategy and principal marketing strategist at Teradyne, has more than 35 years of experience in the semiconductor industry and has held various technical, management and executive positions at Teradyne, Lam Research, LitePoint, TranSwitch and Rockwell Semiconductors. He is currently a member of the SEMI North America Advisory Board.

A long-time SEMI member — and an active participant in SEMI’s Smart Data-AI Initiative — Teradyne (NASDAQ:TER) test technology helps bring high-quality innovations such as smart devices, life-saving medical equipment and data storage systems to market, faster.