SEMI’s annual FLEX Conference & Exhibition returns to Monterey, California, February 18-21, 2019, bringing together nearly 100 speakers on the major developments at the leading edge of printed/flexible/hybrid sensors and electronics technology.

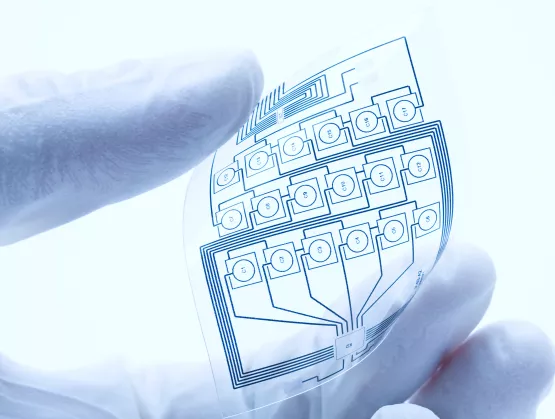

The maturing technology for smarter sensors, in a wider range of flexible formats, is enabling new opportunities across a wide range of applications, from healthcare to agriculture. And that means sensor suppliers need to connect with a broader range of users to build the next generation of innovative outside-the-box solutions. SEMI gathers the flexible/hybrid integration supply chain, leading researchers and potential customers at this annual event to help advance the sector.

The maturing technology for smarter sensors, in a wider range of flexible formats, is enabling new opportunities across a wide range of applications, from healthcare to agriculture. And that means sensor suppliers need to connect with a broader range of users to build the next generation of innovative outside-the-box solutions. SEMI gathers the flexible/hybrid integration supply chain, leading researchers and potential customers at this annual event to help advance the sector.

Collaborative efforts for sensors emerging markets: global health, faster crop development, military monitoring

There’s huge potential for smarter, more accessible sensor systems to detect infectious diseases and aid decision-making for community health workers around the globe, but new technologies and manufacturing methods alone will not be enough to meet the needs of these resource-constrained environments, argues Arunan Skandarajah, program officer at the Bill and Melinda Gates Foundation. He’ll introduce the foundation’s funding and partnering priorities for sensing and imaging for diagnostics and decision support and discuss potential paths forward for development.

Recent advances in plant genomics and high-throughput phenotyping have big potential to enable faster development of crop varieties that better withstand adverse conditions – but that will depend on getting fast feedback from sensor data from the field. There’s immediate need for robust, high-efficiency, low-cost sensor technologies to collect on-the-ground microclimate and resource-use data from tractor-based sensors to field scanners, says Nadia Shakoor, Danforth Plant Science Center. She’ll discuss the sensors researchers need to develop high-yielding, energy- efficient crops that are resilient to variable climates.

Military interest in biosensor patches to monitor human physiology and performance, and other sensor solutions for flexible imaging and point-of-care diagnostics, are also drivers of collaborative research between industry and universities. The Nano-Bio Materials Consortium (NBMC), a SEMI strategic association partnership with the Air Force Research Lab, will offer a workshop to discuss its potential needs, and how to get involved in its development program to create an integrated suite of nano-bio materials and production technology.

Progress in scaling printed/hybrid flexible electronics manufacturing technology

The maturing manufacturing supply chain continues to make progress towards scaling volume manufacturing of higher performance products, with recent innovations in materials and assembly technologies.

Cal Poly researchers will report results from the recent FlexTech benchmark study of the flexible hybrid electronic industry. The study looks at the current state of maturity of the technology, its manufacturing processes, and its main applications while projecting the roadmap for future development. The study covers passives, sensors, batteries, antennas, speakers, PV and energy harvesting, and flexible hybrid integration.

Catch up on new process development capabilities and recent work at the NextFlex Flexible Hybrid Electronics Manufacturing Institute’s San Jose Technology Hub for prototyping and pilot manufacturing. The institute has been adding engineers and projects as it looks towards the next generation of technology for sector growth.

Catch up on new process development capabilities and recent work at the NextFlex Flexible Hybrid Electronics Manufacturing Institute’s San Jose Technology Hub for prototyping and pilot manufacturing. The institute has been adding engineers and projects as it looks towards the next generation of technology for sector growth.

Innovations in scalable assembly of thin die on flexible substrates

Several companies will update on recent progress developing solutions for the industrial-scale, high-yield assembly of fragile thinned die on to flexing substrates. American Semiconductor reports new automated assembly capacity for flip chip die attach and interconnect for devices with up to 100 I/Os and 100um pitch pads. The company also notes that it now has flexible Bluetooth ICs from two major suppliers available in semiconductor-on-polymer chip-scale packages, finally enabling improved wireless capacity for flexible hybrid systems.

CEA-Leti will present its latest developments in flip chip bonding of thin bare die on flex. It uses gold stud bumps on the die, with <150°C thermocompression bonding to PEN Film. The researchers have also developed a wafer-level die process that thins and encapsulates die before removing them from the carrier wafer. systeMECH will also present its results for direct die placement of 300nm die on flexible polyester.

Innovations in materials for easier processing, higher performance

Developments in substrates and processing may now enable use of photonics for laser patterning and flash curing on flexible substrates. Brewer Science will report developments on new polymers that can be quickly and cleanly etched with the mid-UV wavelengths commonly used for laser drilling and etching on printed circuit boards, bringing this improved performance to printed electronics as well. The polymers can be processed at less than 200°C with desirable qualities for substrates, adhesives, protective layers and the like for many electronics applications.

Novacentrix will update on improvements in photonic curing equipment for fast heating to enable the use of high-temperature solders without damaging low-temperature substrates. Atotech will report results from its multiyear initiative to develop lower temperature solder pastes for better performance than SAC-based materials on a variety of substrates.

Printed graphene and carbon nanotubes find applications in sensors and RF devices

Bonbouton will introduce its commercial smart insole using a printed graphene sensor to monitor skin temperature to detect early signs of foot ulcers in diabetic patients. The company inkjet-prints graphene oxide followed by thermal reduction to fabricate graphene supercapacitor electrodes for temperature and pressure sensing.

C2Sense will update on its development of carbon nanotube gas sensors to monitor food condition to prevent waste. The sensitized carbon nanotubes selectively detect ethylene from fruit or ammonia from chicken to accurately track the condition of the foods as they pass through the supply chain. Georgia Tech will report results of printing not only sensors from carbon nanotube ink but even RF and mm-wave diodes and transistors for high-frequency, long-range, low-cost RFIDs.

C2Sense will update on its development of carbon nanotube gas sensors to monitor food condition to prevent waste. The sensitized carbon nanotubes selectively detect ethylene from fruit or ammonia from chicken to accurately track the condition of the foods as they pass through the supply chain. Georgia Tech will report results of printing not only sensors from carbon nanotube ink but even RF and mm-wave diodes and transistors for high-frequency, long-range, low-cost RFIDs.

Innovations in display materials

Materials for flexible displays continue to see innovations – from solutions for foldable displays to plenty of new options for improved transparent conductive films and force-sensitive films. Solotech will introduce a cross-inked polymer that it says offers both high hardness and excellent foldability as a reliable covering for foldable/bendable displays. Atotech will describe its development of selective electroless copper deposition for metal mesh and TFT electrode patterns for touch screens to eliminate the need for costly mask and etching steps after deposition. Chasm Advanced Materials suggests hybrids of the conductive metals and carbon nanotubes offer a promising alternative for flexible transparent conductive films.

C3Nano reports on nanowire ink, fused after printing, for flexible transparent conductors. Peratech will report on its printable pressure touch technology that it describes as high-resolution and low-cost for better localized, force-sensitive touch. Jabil will share the results of its evaluations of five of the available printed force-sensitive sensors. E Ink will introduce new capabilities for its electrophoretic display technology – it’s now possible to write on it with a magnetic stylus, and there’s a variable transmission version for electronic windows.

Next generation technologies from universities and startups

Researchers from major research institutions and startups will talk about developments in flexible/printed/hybrid electronics including innovations in biological/electronics interfaces, via skin or neurons, and demonstrations of piezoelectric and better stretchable circuits.

Emerging technologies for biosensors and human/machine skin interfaces

Georgia Tech researchers will detail their electrical interface with human skin for wireless control of a remote-control car and a wheelchair by electrical signals from the body. They’ve developed a flexible elastomer skin patch patterned with thin film metal/polymer nanostructures made by CMOS processes, and metal pads compatible with conventional reflow soldering. Other Georgia Tech researchers will report their work on better cochlear implants made of encapsulated polymer printed with conductive microcoils for pulsed micro-magnetic stimulation that can focus more tightly on specific areas of auditory neurons. Seoul National University will introduce its flexible organic artificial nerves that can activate an insect’s leg muscle. Researchers there have devised a pressure sensor connected to a ring oscillator that converts the pressure signal into voltage pulses, which are then integrated by a transistor into a signal that replicates a post-synaptic current to communicate with the biological nerves.

Epicore Biosystems will report on its advances in manufacturing and packaging technology that enable its skin-interface electronics and microfluidics systems in thin stretchable format to continuously monitor electrical, acoustic and biochemical signals. The technology is now entering commercial development with industrial partners. GE Global Research will update on its field testing of sweat-sensing devices to monitor hydration.

Emerging technologies for piezoelectric actuators and improved stretchable sensors and circuits

PARC will report on audio speakers made of PVD piezoelectric film on polyimide with inkjet-printed flexible hybrid operating circuits, and Novasentis will talk about its piezoelectric electroactive polymer for different kinds of vibrations for wristband notifications. UTC will share its learnings from deploying large numbers of stretchable flexible hybrid sensors conformably over large areas on aerospace and infrastructure assets to sense temperature, vibration, strain and damage for critical safety.

The Air Force Research Lab reports promising results for stretchable circuits made with liquid metals, which maintain their high conductivity even when stretched. Silent Sensors will discuss its printed flexible manufacturing technology for low-cost, stretchable energy storage and piezoelectric energy harvesting for monitoring the condition of automobile tires.

By Heidi Hoffman, senior director of technology community marketing, SEMI