Nexperia became a standalone company about four years ago after our divestiture from NXP Semiconductors. Last year we started our journey towards smart manufacturing at our back-end factories in Asia by developing a roadmap to help steer us in the right direction.

Our first step to creating a convincing and workable smart manufacturing roadmap was to define the very meaning of smart manufacturing to Nexperia. Since the definition of smart manufacturing varies widely, we started by looking at two different and distinct technology adaptations:

- Physical automation

- Data-driven manufacturing, or using analytics at the core to develop and adopt machine learning and artificial intelligence (AI) models

It is important to find the right balance of investments between physical automation and data-driven manufacturing to steer clear of deployment inefficiencies since only connected solutions deliver full value. Our approach involved the following high-level steps.

It is important to find the right balance of investments between physical automation and data-driven manufacturing to steer clear of deployment inefficiencies since only connected solutions deliver full value. Our approach involved the following high-level steps.

- Meeting with internal management teams for their inputs and examining factory needs and maturity

- Meeting with other semiconductor factory operators, subcontractors and partners to review their smart manufacturing approaches and challenges

- Evaluating our needs and status against the Singapore Smart Industry Readiness Index model

Physical Automation

Evaluating the maturity of available solutions and adaptions by the industry and our own shop floor helped simplify the thought process quite well.

- Logistic automation is not new. Very mature solutions, even for custom layouts and preferences, are readily available.

- Shop floor automation is far more difficult than logistic automation since variability is simply too high.

- Traditional shop floor investments were always driven from quality or OEE perspectives and not necessarily very well connected.

Our approach is outside-in – deploy logistic automation first and then move to the shop floor.

Data-Driven Manufacturing

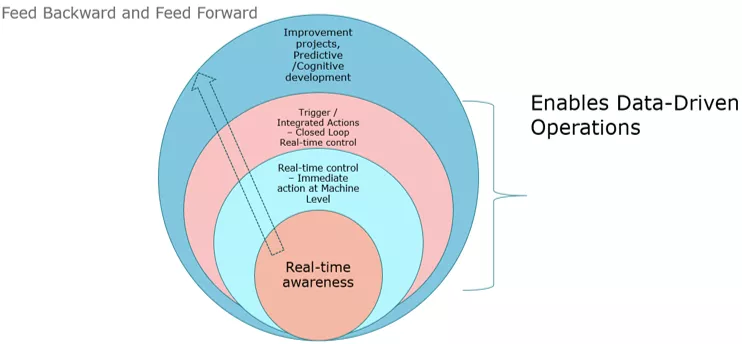

How smart manufacturing becomes depends on the extent to which a factory is data-driven. Enabling data-driven manufacturing requires foundational investments to improve traceability, connectivity and real-time operations. We believe real-time awareness can drive machine-level and closed-loop process control critical for predictive, cognitive control of the shop floor.

Real-Time Awareness and Traceability is at the Core

Developing real-time awareness requires wide-ranging manufacturing protocols. The following focus areas have helped us simplify the challenge:

- Connectivity

- Core systems for areas including MES, quality and SAP

- Analytics and AI

- Digital shop floor featuring one operator interface with real-time control systems

- Readiness of engineers, technicians and managers

Each of these pillars has different level of complexity due to legacy equipment and systems, legacy processes and inexperience of engineers with automation. This makes deployment of data-driven operations a complex challenge. We looked at different project approaches for each of the focus areas:

Each of these pillars has different level of complexity due to legacy equipment and systems, legacy processes and inexperience of engineers with automation. This makes deployment of data-driven operations a complex challenge. We looked at different project approaches for each of the focus areas:

- Core Systems – Build additional technology enablers and roll them out with prioritization planning.

- Analytics – Focus mainly on OEE and yield with automated root cause analysis and predictive approaches.

- Real-Time Control – Merge the initiative with factory-level programs to improve productivity and quality.

With a strong smart manufacturing roadmap, the next challenge is to secure long-term buy-in on the plan and required investments from executive management. Visiting and otherwise connecting with peer sites that have already deployed smart manufacturing infrastructure is vital in this effort. Thanks to SEMI members, we were allowed to visit their factories with our management team for go-and-see tours since seeing is believing in the smart manufacturing journey. Our executives also met with subcontractors and vendors to better understand the value of this transformational undertaking.

A long-term outlook is necessary to successfully develop a smart manufacturing roadmap, and executive commitment goes a long way to ensuring its success. We are excited about our smart manufacturing journey and believe it is a game changer for our factories.

Adarsha MARPALLI is director of Factory Automation at Nexperia B.V.