The SEMI FlexTech R&D program, designed to identify, fund and manage advanced technology development projects in the area of flexible hybrid electronics (FHE), recently completed project FT19-19-190 with SAFI-Tech to create a solder material with a substantially lower melting point than conventional solder paste. The solder is activated in a reflow oven at lower temperatures, which reduces the thermal stresses created by high-temperature processing currently used for new, smaller packaging technologies with more densely packed circuits.

![]() The supercooled liquid metal microcapsules were comprised of BiSn-based alloy both with or without 1wt.% silver. The alloy normal melting point is 139 °C. A conventional solder paste with this alloy requires a reflow processing temperature of 165 °C or higher to form a solder joint. The paste was processed with a maximum temperature of 110 °C, 55 °C lower than the industry standard, and comparable to curing temperatures for electrically conductive adhesives (ECAs).

The supercooled liquid metal microcapsules were comprised of BiSn-based alloy both with or without 1wt.% silver. The alloy normal melting point is 139 °C. A conventional solder paste with this alloy requires a reflow processing temperature of 165 °C or higher to form a solder joint. The paste was processed with a maximum temperature of 110 °C, 55 °C lower than the industry standard, and comparable to curing temperatures for electrically conductive adhesives (ECAs).

The supercooled microcapsule solder paste was stencil printed at ambient room temperature onto a low-temperature PET substrate and formed a full-metal filleted solder joint between common 1206 resisters and silver traces that was more conductive than the reference ECA control materials. SAFI-Tech's solder joint withstood thermal cycling, drop-shock testing, and hundreds of bend cycles of the PET substrate.

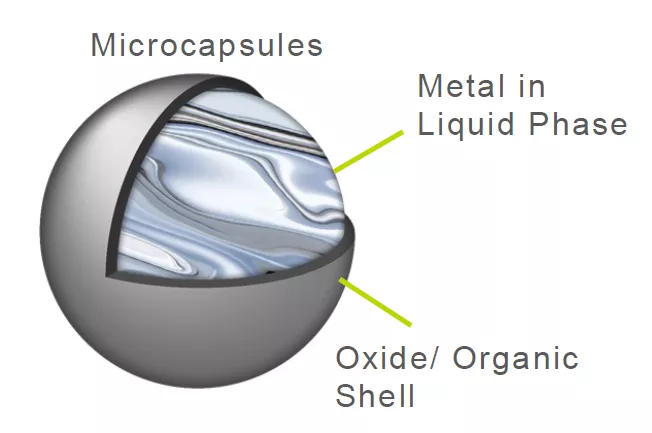

SAFI-Tech supercooled liquid metal particle, or microcapsule.

During the project closeout, Ian Tevis, project manager at SAFI-Tech commended his team for identifying and solving challenges efficiently. Sample evaluation kits of the new materials are available and can be mixed on site. SEMI FlexTech members are encouraged to request the kits for evaluation. If interested, contact Darin Heisterkamp at darin@safi-tech.com.

The project totaled $522,806, with 52% funded by the contractor. The U.S. Army Research Laboratory (ARL) provided the SEMI FlexTech funding.

To learn more about the project and paste products, contact SAFI-Tech, or attend the upcoming FLEX Conference, July 11-14, 2022 in San Francisco, California. SAFI-Tech will present one of the more than 70 technical papers at the event focused on flexible electronics innovations. The FLEX Conference will co-locate with SEMICON West 2022 at the Moscone Center.

Gity Samadi is program manager at SEMI-FlexTech.